How to calculate the Carbon Emission of building curtain wall should focus on " Embodied carbon "

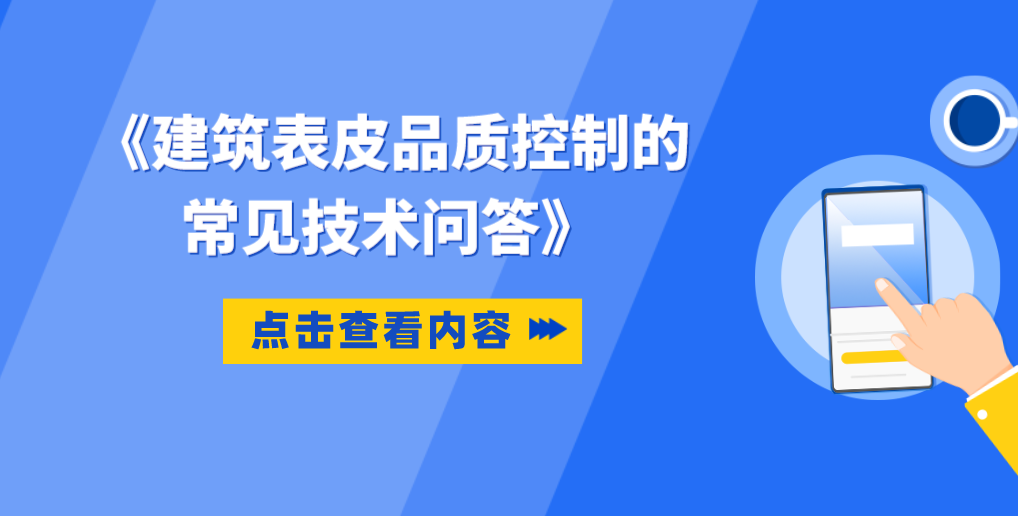

According to the statistics of the Global Construction Industry Status Report released by the GlobalABC in 2019, in the total global carbon dioxide emissions in 2018, the construction industry accounted for 39% of the global carbon emissions, of which 28% came from the operation stage of the building and 11% came from the production stage of building materials.

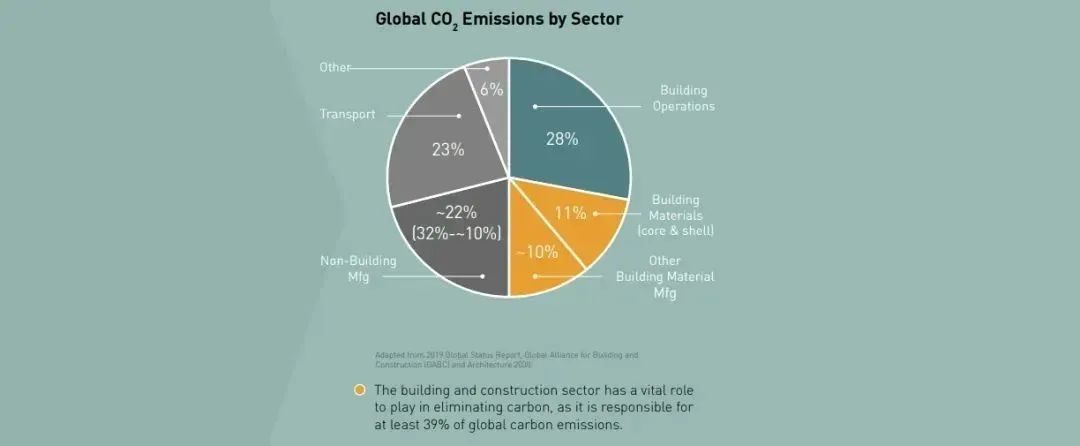

But China's national conditions are different. Due to the relatively large number of new projects in China, according to the " 2022 China Building Energy Consumption and Carbon Emissions Research Report " jointly issued by the China Association of Building Energy Efficiency and Chongqing University in early 2023, the total carbon emissions of the whole process of construction in China in 2020 will be 5.08 billion tons of CO2, accounting for 50.9% of the total carbon emissions in the country. Among them, the carbon emissions in the production stage of building materials are 2.82 billion tons of CO2, accounting for 28.2% of the total national carbon emissions; the carbon emissions in the construction operation stage were 2.16 billion tons of CO2, accounting for 21.7%.

This is very different from the global data of the GlobalABC. The carbon emissions of building materials are higher than the carbon emissions in the construction operation stage.

▲ The total carbon emissions and proportion of China 's construction process in 2020

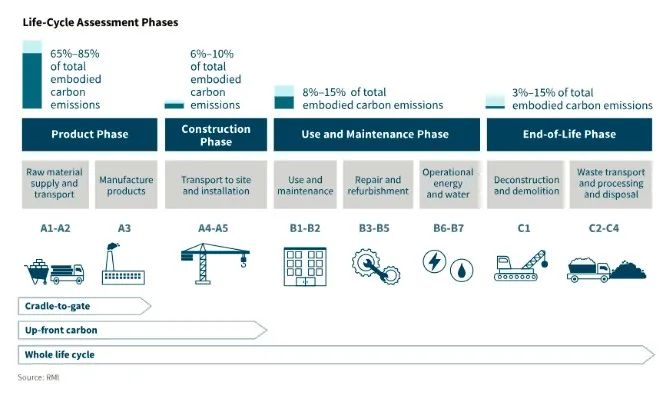

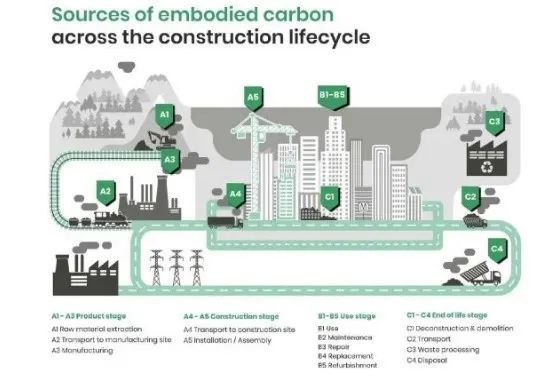

Carbon emissions have always existed in the FLC of construction projects. Carbon emissions in the whole life cycle of buildings are the sum of greenhouse gas emissions generated by buildings in the production and transportation, construction, operation and demolition stages of building materials related to them ( expressed as carbon dioxide equivalent ). It is called " Embodied carbon " and " Operational carbon. "

"Operational carbon" is the carbon emitted from the energy consumed by operating buildings, including carbon emissions from the burning of fossil fuels, directly or indirectly, for heating and electricity.

"Embodied carbon" is the carbon associated with materials and construction processes throughout the life cycle of a building, including carbon-containing greenhouse gas emissions generated during the manufacturing, transportation, installation, maintenance and disposal of building materials. That is, the carbon in the production stage of building materials, which accounts for a higher proportion (28.2%) as mentioned in the 2022 China Building Energy Consumption and Carbon Emissions Research Report.

▲ The whole life cycle of a construction project

From the figure above, the production of building materials is A1~A3 stage; construction process is A4~A5 stages; operation and maintenance for B1~B5 stage; removal and disposal are C1~C4.

It can be expressed by the formula:

Carbon embodied by buildings = building material production (A1~A3) + construction process (A4~A5) + use (B1~B5) + removal and disposal (C1~C4)

Building Operational carbon = Operating (B6~B7)

▲ Generation stage of implicit carbon and operational carbon

To reduce Operational carbon, from a design point of view, you can use efficient machinery and equipment, the use of renewable energy such as photovoltaic, the use of recyclable rainwater, the use of better energy-saving performance of the enclosure wall, to reduce the carbon emissions generated in the operation.

In China, the government has issued a lot of energy conservation laws to continuously improve our energy conservation standards, so that the carbon emissions in our operation process are gradually reduced.

Ways to reduce Operational carbon curtain wall:

Excellent thermal insulation maintenance structure;

Facade shade;

Ultra-low energy consumption window, ultra-low energy consumption glass curtain wall;

Using BIPV, the building facade and roof are equipped with photovoltaic panels, and the selection of efficient photovoltaic power generation components can provide electricity.

Ways for buildings to reduce Operational carbon:

The hot water system adopts air source heat pump;

Project functions The room lighting uses LED lamps and other energy-saving lamps, intelligent lighting control system;

Natural ventilation;

Natural lighting;

Roof greening;

Intelligent management system.

Embodied carbon is different from Operational carbon, which comes from fossil energy consumption in the operation of the building after completion, such as electricity and natural gas required for heating, cooling, ventilation, lighting and power plug loading of the building. Operational carbon emissions can be reduced with building energy efficiency improvements and the use of renewable energy, while the emplied carbon is locked in when the building is completed.

In the United Nations Environment Programme's 2022 Global Status Report on the Construction Industry, it is noted that while Embodied carbon contributes significantly to global greenhouse gas emissions, it has not been adequately addressed in strategies to reduce emissions from buildings. Most building codes and regulations address the reduction of Operational carbon, such as the energy needed to light or cool indoor environments, but typically do not require the calculation of Embodied carbon, which is the emissions from material extraction, manufacturing, construction, maintenance and disposal. However, the carbon embodied in the material has not been particularly well reduced or paid attention to.

In buildings, the main structure has the largest proportion of Embodied carbon, which is also the focus of Embodied carbon reduction. The Embodied carbon emissions of the curtain wall account for about 10% to 20% of the entire building production and construction stage. The key to the Embodied carbon of the curtain wall is the choice of materials, carbon assessment should be carried out early in the design, and the system of the curtain wall should be determined.

Curtain wall materials have Embodied carbon, glass, aluminum profiles, from mining to factory processing, and then to the construction site installation process, the later use and maintenance of the building update, and finally to the end of the building life cycle demolition will produce carbon emissions.

▲ Hidden sources of carbon throughout the life cycle

Domestic curtain wall materials are mainly aluminum profiles and steel, especially aluminum profiles account for a large part of the entire curtain wall, aluminum profiles in the production process will consume a lot of energy, aluminum profiles are basically produced by electrolytic aluminum, and more than 80% of domestic power plants use thermal power, which leads to a lot of energy consumption in the production process of profiles. Produces a lot of carbon emissions.

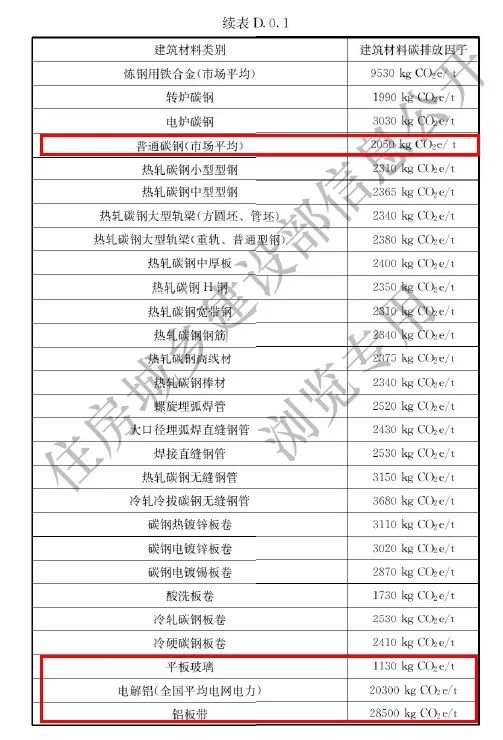

In China, the "GBT51366-2019 Building carbon emission Calculation Standard" issued in 2019 mentioned the "carbon emission factor", and the production of 1 ton of electrolytic aluminum will produce more than 20,000 kilograms of carbon dioxide emissions, so the carbon emissions of aluminum plates and aluminum profiles are very high.

In comparison, the carbon emissions of steel will be much lower, and the carbon emissions of glass are lower than that of steel.

▲ Carbon emission factors of building materials

According to some relevant data in the current third-party carbon footprint database of building materials, it is not difficult to see that the carbon emissions of aluminum and aluminum products are 10 times that of steel, and the carbon emissions gap between aluminum and stone is also huge, stone belongs to low-carbon materials, and aluminum and aluminum plates belong to high-carbon materials. The carbon emissions of ceramic board, glass, UHPC and GRC are between metal and stone.

▲ Carbon emission factors of commonly used building materials for curtain wall doors and Windows

Therefore, it can be concluded that the carbon emission factor of building materials and the amount of materials determine the amount of carbon emissions. Therefore, the choice of materials with small carbon emission factor is the designer's consideration, while improving the production process and reducing the carbon emission factor of building materials is the focus of building materials manufacturers.

In the building materials, wood is a very low-carbon environmental protection material, the carbon emissions of wood structure is very low, heavy wood structure building is the current market hot sustainable products, these woods are glued, used to create large structural beams, heavy wood buildings have obvious carbon reduction advantages.

▲ SuperHub Meerstad Market

Wood can also be used as the keel or decorative material of the curtain wall system, which can greatly help the building facade reduce carbon emissions.

▲ Wooden keel curtain wall

So, how to calculate the Emboild carbon emissions of the building curtain wall?

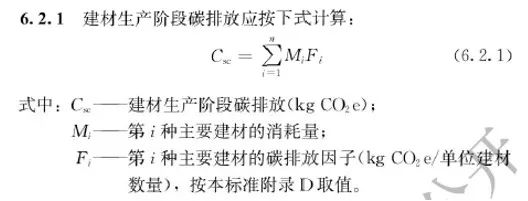

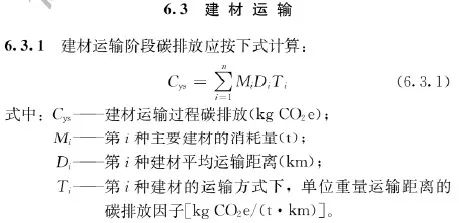

According to the domestic building carbon emission calculation standard "GBT51366-2019 Building carbon emission calculation standard", we calculate the carbon emission of the curtain wall in the curtain wall design stage, and we need to consider: carbon emission in the production stage of building materials, carbon emission in the transportation stage of building materials, and carbon emission in the demolition stage.

▲ Carbon emission calculation in building production stage

▲ Carbon emission calculation during building transportation

Taking an office building as an example, it is necessary to consider the Emboild carbon calculation of the FLC of the building curtain wall at the early stage of design. The curtain wall may have multiple systems such as stone curtain wall, glass curtain wall, and metal plate curtain wall, and then calculate the carbon emissions of each curtain wall system separately.

Such as stone curtain wall system, how much is the amount of curtain wall material per square meter? According to "the quantity of building materials * the carbon emission coefficient of the building materials", how much carbon emission does stone account for? How much carbon does steel keel account for? How much carbon does rockwool account for? Break down the carbon emissions of a building point by point and look at the carbon emissions of a certain curtain wall system.

In the design of curtain wall scheme, it is necessary to compare the carbon emissions of different curtain wall systems, such as the glass curtain wall system, respectively analyze the unit curtain wall and the frame type. If you do the unit curtain wall, how many aluminum alloy components will be contained, how much rock wool will be, how much glass will be, and finally calculate the carbon emissions in the production and construction process. If the frame type curtain wall is used, how much carbon emissions will the curtain wall have?

Industry personnel should be able to see here that the aluminum profile content of the unit curtain wall is high, and its carbon emissions will be more. If a frame-type curtain wall system is used, its carbon emissions will be relatively small.

Therefore, the carbon emissions of the building curtain wall need to adopt the FLC and system thinking method, thinking about the Embodied carbon plus Operational carbon, the carbon emissions of the whole building curtain wall will be reduced or increased. For example, low K value energy-saving curtain wall, lower K value can reduce Operational carbon in the operation stage, but the increase in the use of aluminum alloy profiles will bring about an increase in Embodied carbon, so for the carbon emissions of the whole building, it is necessary to comprehensively consider the process of reducing K value, if the increase of Embodied carbon is avoided, and comprehensively judge the Operational carbon and Embodied carbon of the building.

▲ Near zero carbon Building (Zhongjian Binhu Design Headquarters)

When designing curtain wall, in addition to the aspects of architectural aesthetics, curtain wall performance and curtain wall cost, we also need to consider the material selection and system selection of curtain wall from the perspective of carbon emission, and pay attention to the two aspects of Embodied carbon emission and Operational carbon emission. Especially for the goal of peak carbon dioxide emissions in 2030, Embodied carbon is the main component. Special attention is needed.