Huanglongxi Valley · Tahiti

-

Location

Sichuan

-

Client

Chengdu Youpindao Land Group Co., Ltd

-

Design

gad

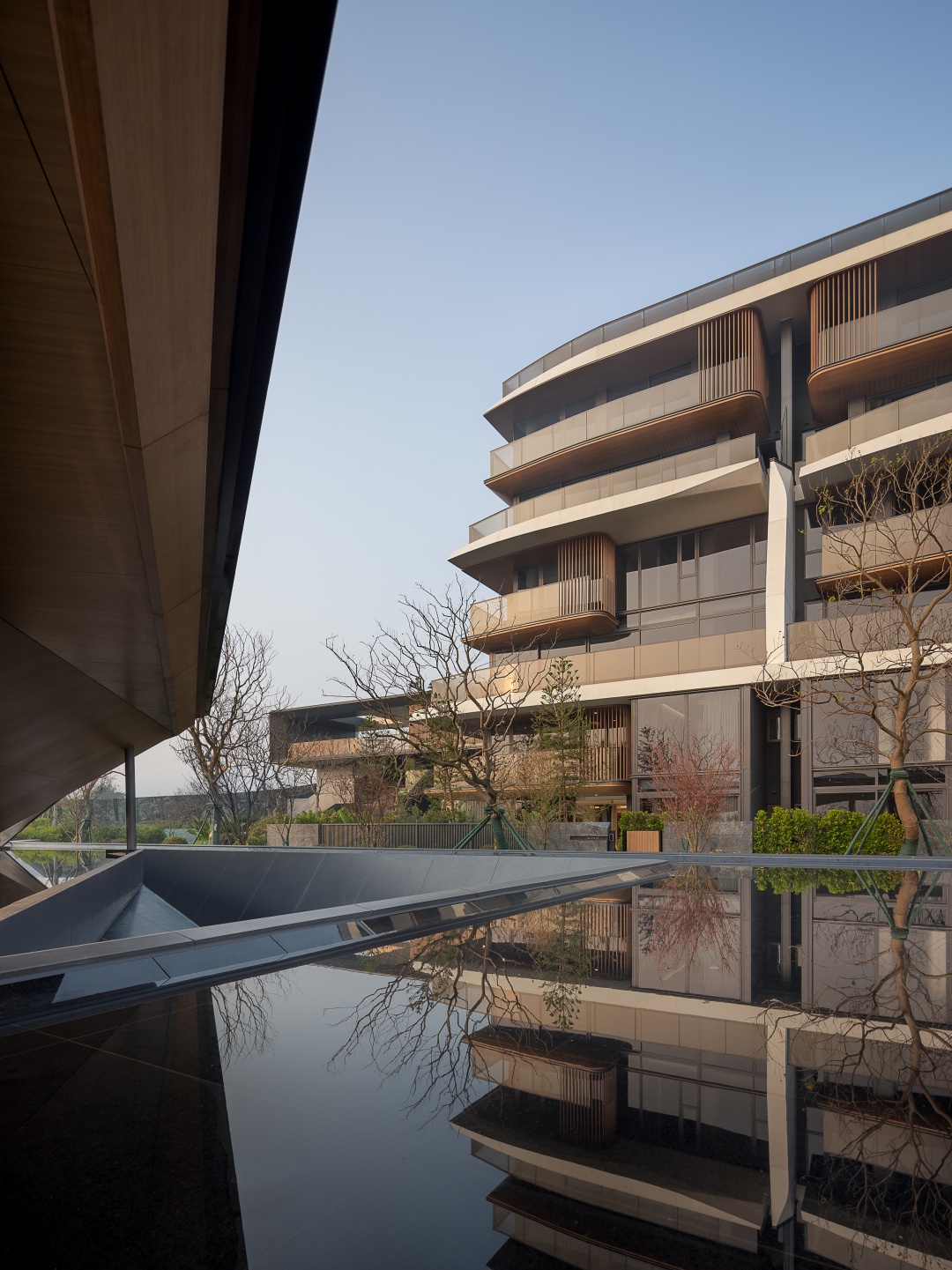

▲ Physical Display Area - Realistic Picture

Tahiti, a gem located by the ancient town of Huanglongxi in Tianfu New Area, not only enjoys a well connected transportation network, but also boasts abundant natural landscape resources. Tahiti, covering an area of approximately 232 acres, is perfectly embedded in the core area of Huanglong Creek Valley. With a low plot ratio of only 1.18, it ingeniously presents residents with an ideal low-density, high-quality living space. The superior geographical location makes it a link between Chengdu Biotech City, Science City, Tianfu CBD, High tech Financial City, and the main urban area of Chengdu, greatly facilitating residents' daily travel and work needs.

In the design phase, the Tahiti design team cleverly utilized the natural height difference of about 10 meters between the lake and landscape points on the east side, instead of using traditional peak shaving and valley filling techniques. Instead, they followed the natural trend and made the building progress layer by layer like mountains, perfectly interpreting the beauty of the Eastern philosophy of "seeing mountains is still mountains".

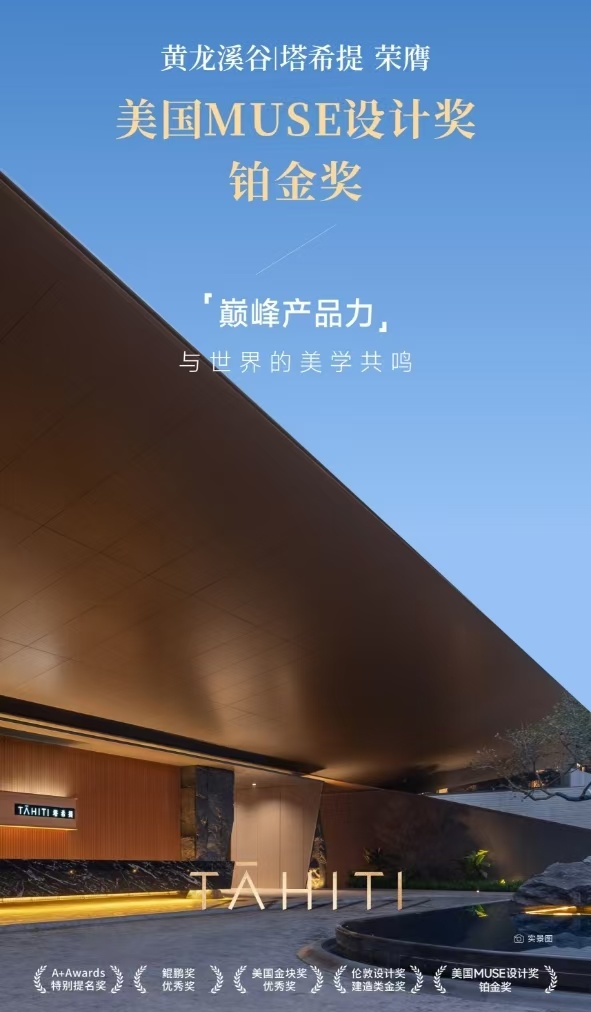

Since its inception, Tahiti has won numerous international awards for its unique design concepts and unparalleled craftsmanship, including the A+Awards Special Award, the American Gold Award for Excellence, the Kunpeng Award for Excellence, and the Gold Award in the Architecture Residential Construction category at the Better Future London Design Awards.

▲ Tahiti Awards Overview (Latest)

Of particular note is that in the latest award announcement, Tahiti has been honored with the MUSE Design Award - Platinum Award in the United States. This honor not only fully recognizes the outstanding design capabilities of the project, but also highly appreciates its innovative spirit and sustainable development concept. Behind this series of achievements lies the design team's meticulous attention to curtain wall design and unwavering pursuit of excellent engineering quality.

▲ Physical Display Area - Realistic Images

In the stacked villa products displayed in the physical display area, a large grid lifting sliding system door is used, with slender frames and good glass transparency. Some parts are designed without columns, providing residents with a 270 degree panoramic view and achieving seamless connection between indoor space and external natural landscape.

In addition, the exterior design also incorporates elements such as European grey premium privacy glass, hot wood grain transfer printing grille and aluminum veneer, high-grade roller coated honeycomb aluminum plate and aluminum veneer with imitation embroidery texture, non combustible inorganic film decorative wood grain ceiling, high-performance decorative concrete HPC system lines, imitation bamboo colored glazed clay panel wall, Bali platinum luxury stone corridor, and chopped axe surface variable cross-section stone column wrapping.

These exquisite design inspirations complement high-performance building materials, jointly constructing the most ornamental stacked villa complex on the market, and providing residents with an ideal living environment that is hidden luxury, relaxed, and harmoniously coexists with nature.

The overhanging eaves of the car lobby are made of roll coated honeycomb aluminum panels due to their long length, greatly improving the flatness of the panel surface. The eaves lines are made finer to ensure detail scale, using aluminum alloy molded profiles, and the facade lines appear straight and upright.

▲ Realistic picture of flying eaves

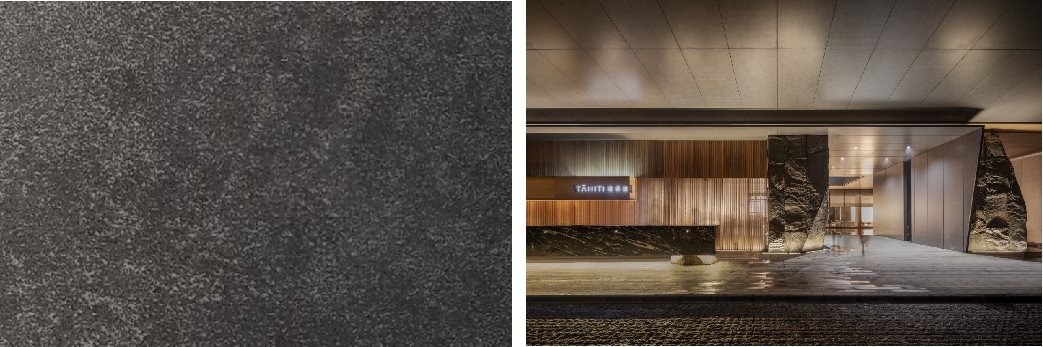

Material selection: Approximately 25mm thick honeycomb aluminum plate, with a dark gray imitation rust texture on the surface, and a pre roll coating process for the finish.

▲ Application of dark gray imitation embroidery texture

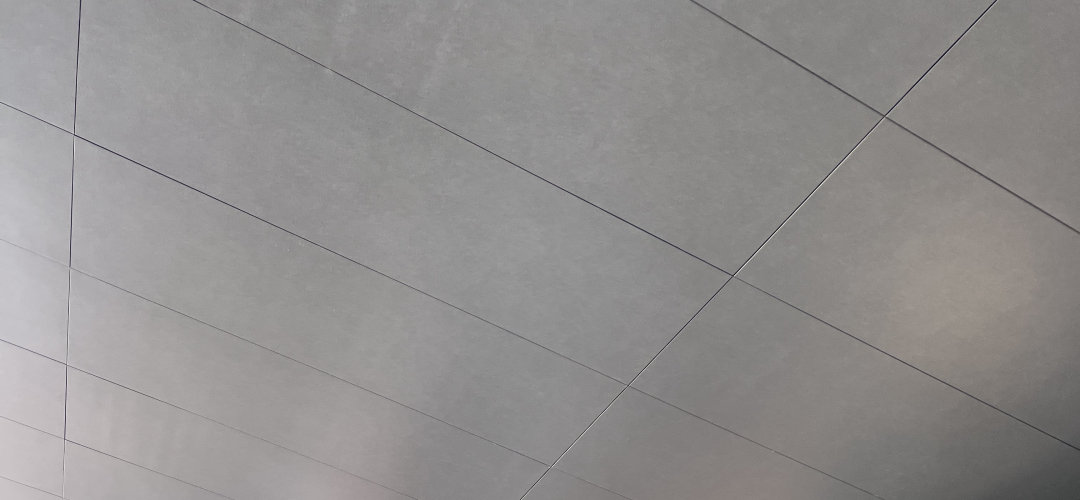

Process design: The grid size is controlled within the maximum size range of the honeycomb board to ensure flatness, while achieving the maximum plate size to ensure flatness; Two types of dry hanging systems are used for hanging, including aluminum alloy hangers and corner brackets with screw connections. The joint width is controlled according to the ultimate effect. The ceiling adopts 6mm dense splicing without glue, and the visible surface of the aluminum alloy corner brackets and keel is treated with dark paint spraying; Add details to the entrance wall and use 12mm aluminum alloy grooves for joint design; The roof facing surface is sealed with the same color sealant, and the joint width is also controlled at 6mm.

▲ 12mm seamless metal groove details

▲ 6mm dense splicing details

Construction precision: The maximum size of a single honeycomb panel with a large overhanging eave at the entrance of the car lobby is 1.2x3.96 meters, and the total length of the outer overhanging eave is 46.5 meters. The flatness error of a single aluminum plate is controlled within 1mm, and the cumulative error of the total length is controlled within 5mm.

Tahiti's metal wall also uses the same materials and craftsmanship, with a 12mm natural seam glue free process and aluminum alloy groove details added to the joint position. The interior decoration technology is applied to the exterior decoration, making the facade more exquisite. The vertical height metal plate further enhances the spatial experience of the lobby entrance.

▲ Overview of Metal Walls

▲ Realistic Details

Material selection: Imported Brazilian black stone with deep gray axe chiseled surface is selected, which perfectly matches the natural effect of axe chiseled surface and the precipitation of natural stone with the emphasis on wild luxury style in the lobby. The finish is sprayed with a certain proportion of clear varnish to enhance texture and strengthen visual effects.

▲ Chopping Axe, Bread Pillar, Stone

Process design: Considering safety and construction convenience, the design team controlled the maximum thickness of the board. During construction, chemical anchor bolts are used instead of conventional back bolts for dry hanging, and 4mm splicing joints are not glued.

Construction precision: The stone slabs are uniformly arranged in the factory, and the thickness and weight of each slab are strictly controlled to ensure a natural and smooth effect after being installed on the wall.

▲ Realistic Details

▲ Realistic picture

Throughout the main structure of the building, the hidden frame glass railing sits on the horizontal HPC decorative lines, perfectly connecting the material color, texture, and two systems.

Material selection: The glass railing uses European grey low transparency and low reflection glass, which can maintain consistency with the door and window glass and weaken the shadow box effect of the terrace structural beam. The decorative lines are selected as beige smooth HPC, emphasizing delicacy and thickness while eliminating dullness.

Process design: The glass railing is hung below and adopts a hidden frame design. The bottom is connected to HPC and transitions to aluminum alloy profile lines to maintain a clean and complete overall effect of the exterior finish; Similarly, the horizontal HPC plates between layers are made of flat plates, with locally variable cross-section plates, and the joints are sealed with the same color adhesive to achieve the overall effect of the plates while meeting waterproofing requirements.

The suspended ceiling is replaced with imitation HPC aluminum panels to improve the safety of the curtain wall. To solve the problem of light colored materials easily flowing and accumulating dirt, the top surface of the lines and the facing surface of the facade are designed with a natural slope of 3% or greater to avoid water accumulation and hanging. At the same time, the HPC board surface has been treated with a new type of waterproof coating material, and the board surface itself also has a certain degree of self-cleaning.

Construction precision: coordination and management of multiple materials, different interfaces, and different units; Align the HPC lines, imitation HPC aluminum plates, and glass railings in the terrace area, and disclose them to the standard for positioning.

Material selection: Use a 20x20mm aluminum alloy grille tube with a spacing of 20mm. The finish adopts wood grain heat transfer printing technology, imported film coating, natural wood grain, and good weather resistance.

Process design: Assemble aluminum alloy tubes into a hyperbolic shape, and bend the sealing tube in a single loop; The grille tube adopts an aluminum alloy combination form, with hidden nails and no glue process. The grille end is sealed delicately, and the overall effect is lightweight.

Construction precision: In order to achieve hyperbolic design, on-site positioning and sizing of the arc position, assembly of individual grid pipes, and on-site sizing and cutting of the overhanging end, extremely high construction precision is achieved to achieve smooth hyperbolic shape.

▲ Detail drawing of curved grille

▲ Large size lifting sliding door

▲ Large size french window

Material selection: Considering the transmission and reflection issues of the glass surface after the construction of the building complex, we still choose European grey low transparency glass and dark grey profiles, which match the architectural style in color while meeting privacy and overall aesthetics; The decorative surface adopts imported powder spraying technology, with strong metallic texture and high weather resistance; In terms of configuration, high-end system doors and windows, multi cavity insulation profiles, and double silver insulated energy-saving glass are used, which not only achieve thermal insulation, but also meet the smooth touch of sliding doors and windows.

Process design: Adopting a 2.4mX2.8m single leaf sliding door with a large opening area, the doors and windows are designed without borders, with the top hidden in the ceiling and the bottom track unobstructed, embedded in the ground for easy use. The vertical design adds groove details, visually making the window frame more slender, upright, and exquisite.

Construction precision: The upper and lower frames of doors and windows, as well as the ceiling and floor, are properly sealed to ensure maximum transparency of the glass.

▲ rench window details

The contrast between the large-sized glass skylight surface and the wood grain grille highlights the collision beauty between modernity and primitiveness.

More exterior facade designs

▲ HPC sailboat design

Tahiti's building facades have a large number of curves, arcs, and radians that require extremely high precision in the civil engineering of the main building, with errors controlled within millimeters.

The common exterior materials for straight facades are usually synchronized with the main construction, while the Tahiti project requires a professional exterior design team to conduct in-depth research on the technology, performance, construction feasibility, and cost-effectiveness of various materials from the architectural scheme stage due to its unique shape and innovative material selection, and to conduct overall 3D modeling to fully simulate and predict possible conflicts between different professions. After the main structure is capped, the exterior team will conduct on-site scanning, molding, and correction work before starting the prefabrication of HPC decorative panels in the factory to minimize errors and ensure installation accuracy.

The architectural fa ? ade of Tahiti's villa pioneers eliminates the stubborn problem of irregular planes caused by irregular facades through the reasonable arrangement design of different materials and strict construction requirements.

▲ Realistic Indoor Water Curtain Scene

Tahiti has added profile details at different material junctions, such as aluminum alloy profile grooves at the junctions of HPC eaves and ceiling aluminum panels, ceiling aluminum panels and wall stone, and HPC and paint, which can reduce construction difficulty and increase detail quality.

More construction scenes at a glance:

Process control snapshot

▲ FORCITIS&Youpindao

In the pursuit of architectural aesthetics and functionality, the Tahiti project team strictly controls construction details, carefully selects materials, and ensures project quality. The following photos document the entire process of the project from design to implementation, demonstrating the efforts to transform ideas into reality.

The FORCITIS consulting team and the Youpindao exterior design team have been closely collaborating since the design phase to ensure the successful implementation of the design. To cope with challenges such as on-site conditions, rainy season construction, and cross disciplinary operations, a detailed construction plan was developed in advance and specialized simulations were conducted. The close cooperation between the professional team of the construction party, the curtain wall consultant and design team, and the exterior construction unit makes the project expected to become a market benchmark.

The current demonstration area is only one thirtieth of the entire Tahiti, with almost no standard buildings, standard floors, and extremely complex facade shapes and changes. The FORCITIS consulting team has been cooperating since the proposal stage, from material selection to on-site inspections, committed to professionalism and attention to detail, and is fortunate to contribute to the quality implementation of the project.

If architecture is the art of exploring people and space, then Tahiti's way of life is a more detailed evolution of this art. Currently, the project demonstration area has been presented in real life, and people from all walks of life are welcome to come and taste it, and join the new era of luxury homes in Chengdu. FORCITIS will be committed to exporting and implementing better products for the national high-end market and exterior industry.

-

Shijiazhuang Sunac Central Business District Exhibition CenterThe first ultra-low energy public building with a large curtain wall system in Shijiazhuang.

Shijiazhuang Sunac Central Business District Exhibition CenterThe first ultra-low energy public building with a large curtain wall system in Shijiazhuang. -

Hangzhou Renheng Changxiang Jianglan BayThe architecture is integrated into the urban skyline and the artistic language of the international community is made more 'contemporary'.

Hangzhou Renheng Changxiang Jianglan BayThe architecture is integrated into the urban skyline and the artistic language of the international community is made more 'contemporary'.