Dongguan Huawei Songshan Lake Tuanbowa Production Base

-

Location

Dongguan

-

Client

Huawei

-

Building Area

569100㎡

-

Service

Project Management

Dongguan Huawei Songshan Lake Tuanbowa Production Base

Huawei Songshan Lake Tuanbowa Production Base is located in Dongguan, Guangdong Province, which is an important experimental base laid out by Huawei. It is strategically positioned as an important equipment production base of Huawei headquarters, and will be equipped with Huawei's high-end production line to provide important technical support for the development of terminal consumer goods and precision components.

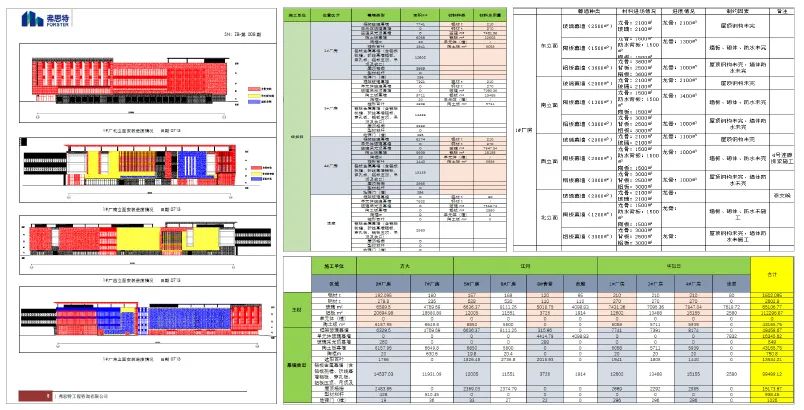

△Project renderings

The industrial project is an important part of the development strategy of Huawei Tuanbowa Base, with a total construction area of 569,100m2 and consisting of 11 single buildings, which are mainly divided into standardized factory buildings, office buildings, canteen basements and passages, with supporting sub-items. After the completion of the project, it will become a terminal wireless manufacturing plant (Manufacturing Department) and build a world-class intelligent manufacturing benchmark factory.

△Project renderings

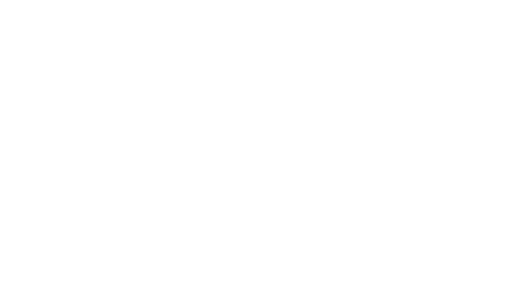

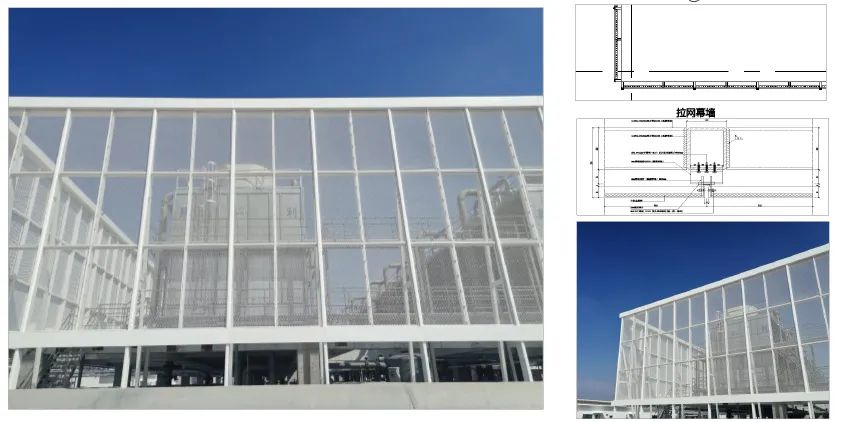

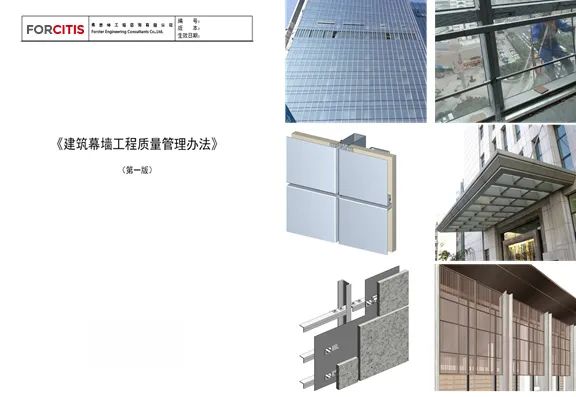

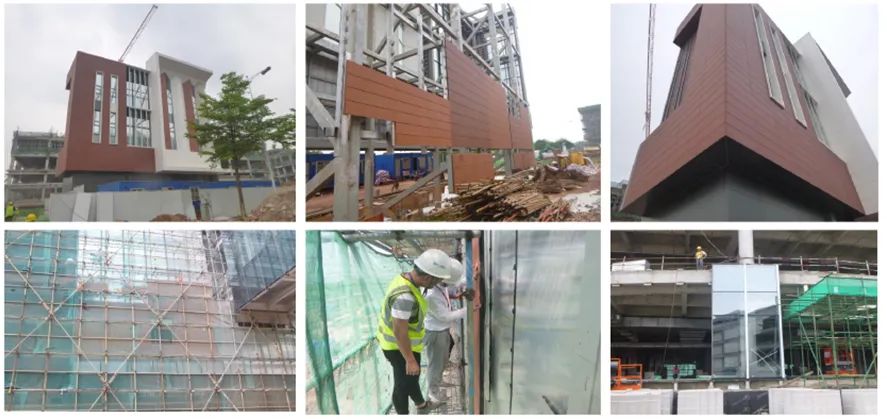

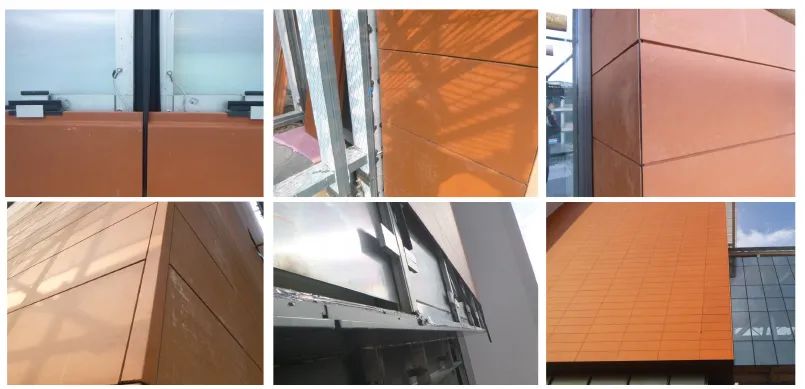

The main curtain walls used in the project are glass curtain wall, ceramic plate curtain wall and metal curtain wall. Th engineering management engineers of FORCITIS cooperate with Huawei to control the quality of curtain wall through factory inspection, construction site, test side station and material acceptance.

△curtain wall system

△Shuttle louver and glass curtain wall

△The glass curtain wall that is bright in vertical direction and hiding in horizontal direction

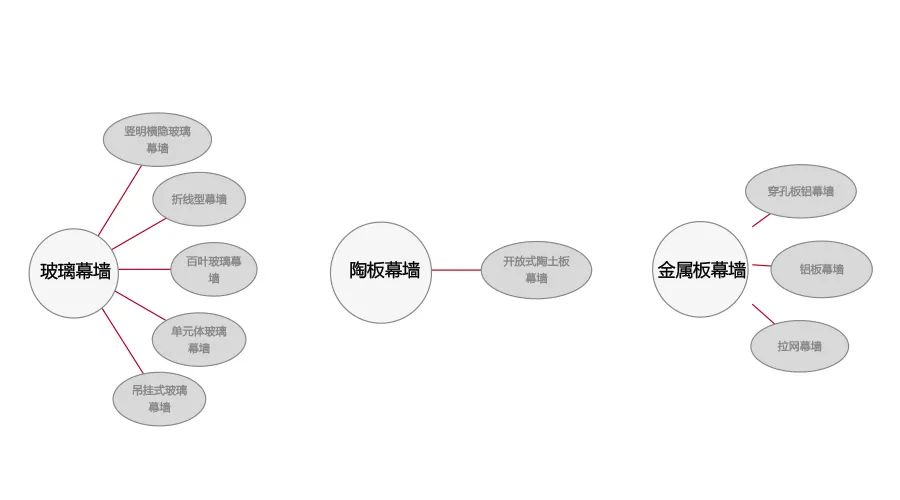

△ Unit glass facade

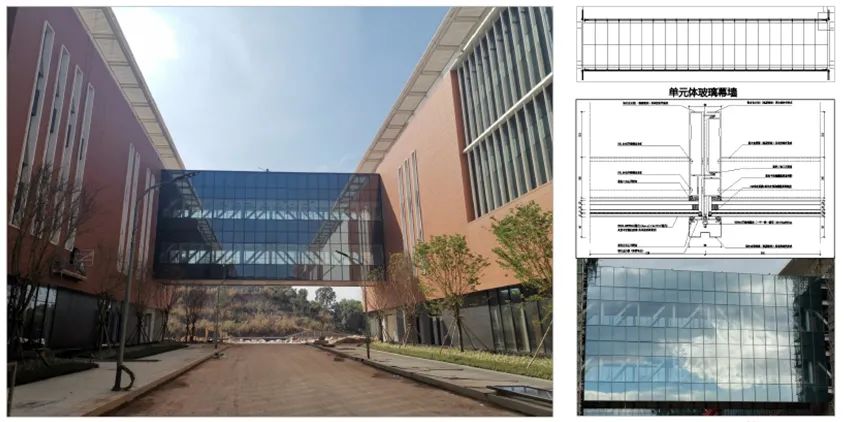

△Pottery clay slab facade

△Folded line/Bright in vertical direction and hiding in horizontal direction/Perforated plate/Aluminum plate/Combined facade

△Pull net facade

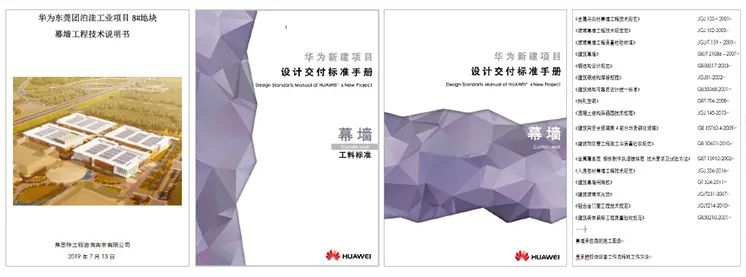

Patrol inspection standards

The quality supervision standards are based on the design requirements, materials and technical standards (technical specifications of curtain wall) and quality requirements of curtain wall construction of the project, and relevant specification documents of curtain wall industry (if the latest specification is available, the latest implementation version shall prevail). See the following table for details:

△Huawei quality supervision standards

△FORCITIS quality supervision standard

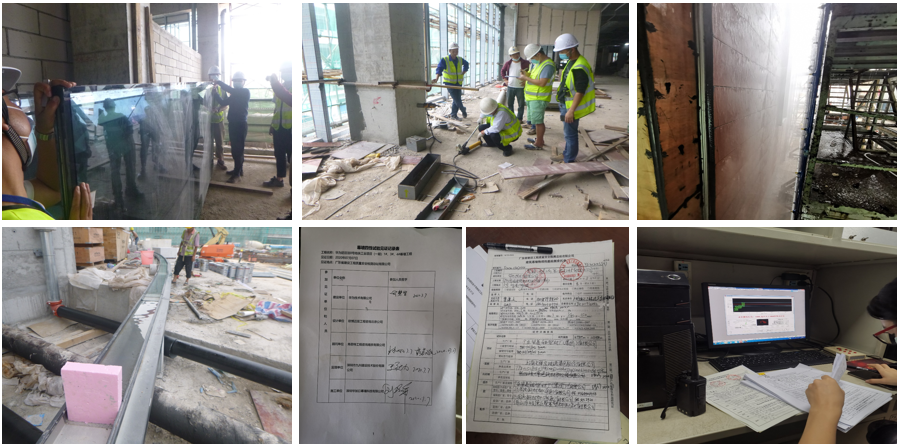

Construction design management

Hold regular design meetings and conduct joint review of construction drawing design. We use FORCITIS curtain wall drawing review standard process and drawing review key points management system, and use long-term accumulated and rich drawing review experience to conduct all-round review on drawing design, cost optimization, calculation book, landing effect and other aspects to ensure that the construction drawings meet the design requirements and national standard requirements, and also ensure the final presentation of project effect under the optimal control of project cost.

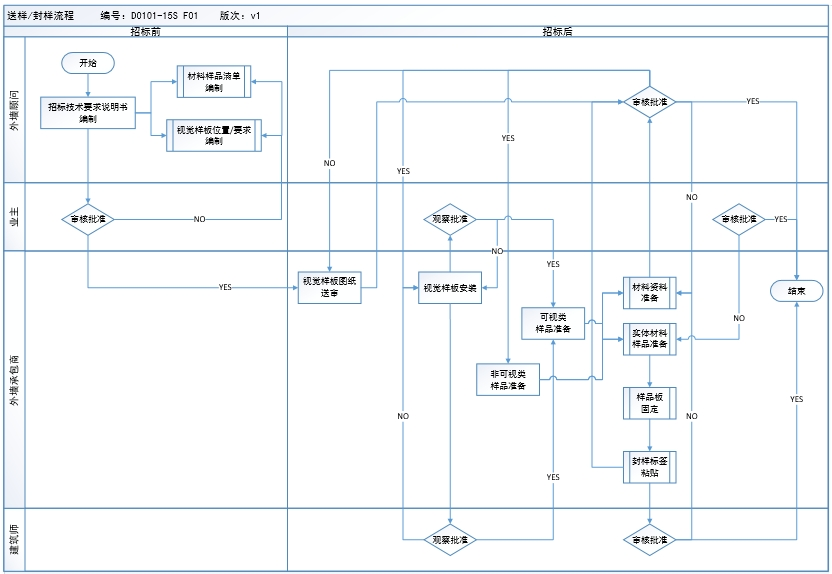

Construction sample sealing management

Require model in advance and model review. Since the model can reflect the effect details of the whole project from point to surface, the owner can intuitively understand the important and difficult points of construction before formal construction, and put forward prevention and solution suggestions, so that the later construction can be carried out smoothly, and the problems can be found and solved in advance.

△Construction sample sealing management flow

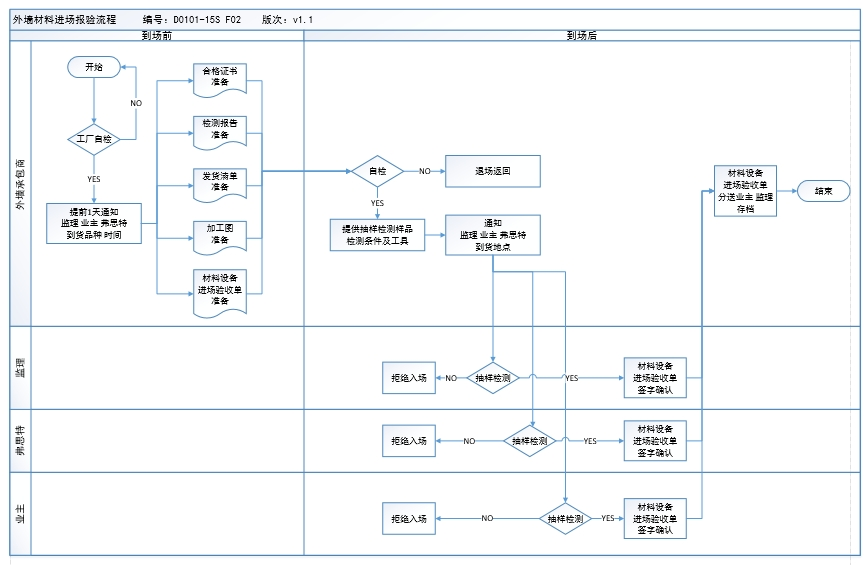

Material quality management

Material control is the foundation of installation, and controlling the entry time of materials is an important guarantee for the successful completion of the project. Material quality management is carried out by comprehensively controlling material entry quality, material re-inspection plan, material sample sealing progress, material re-examination content, main and auxiliary material processing progress and entry.

△Flow chart of material quality management

△Sampling inspection of materials entering the site and warehouse materials

△Unqualified material by sampling inspection are rejected

△Unqualified material by sampling inspection are rejected

△Material processing factory inspection

Construction progress management

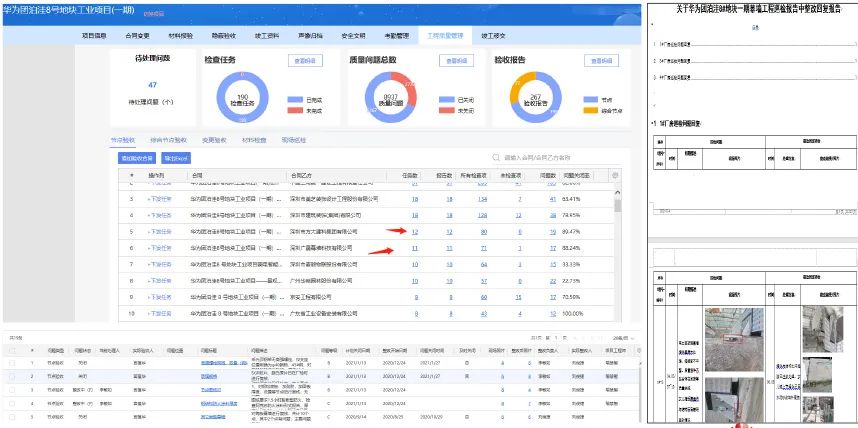

In the whole process of the construction project, the planned progress with the actual progress are compared. If the actual progress deviates from the planned progress, whether the progress is accelerated or delayed, it will have an impact on the overall plan and bring problems to the construction process. Effective measures should be taken in time for making adjustment, assist the owner to find out the reasons and resolutely carry out the correction.

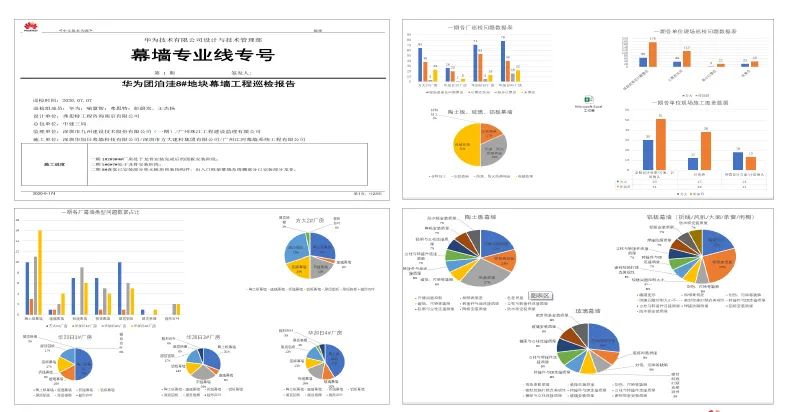

△Daily reports are provided every day, and visual progress, material/installation data are provided every week

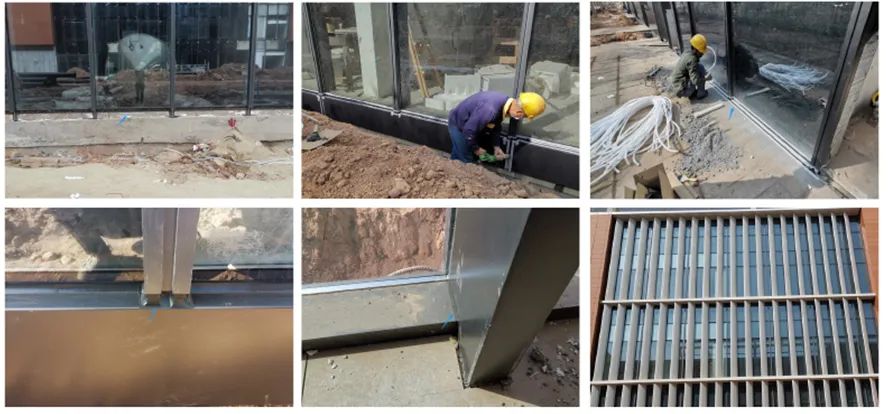

Construction site management

During the period of stationing on site, it checks the construction quality every day, and prepare daily inspection report, weekly inspection report and monthly analysis report; Visual data analysis is conducted for the problems found in inspection, in order to carry out rectification and closed loop of quality problems in a scientific and orderly manner, and escort the project construction quality.

△Data analysis

△Quality control compliance performance (facade with ceramic plate)

Quality control compliance performance (glass facade)

△Inspection construction site (carry out spot check of glass flatness on site, drawing, water storage, wind pressure resistance, air tightness, water tightness and in-plane deformation)

△Visual table

△Scheme report

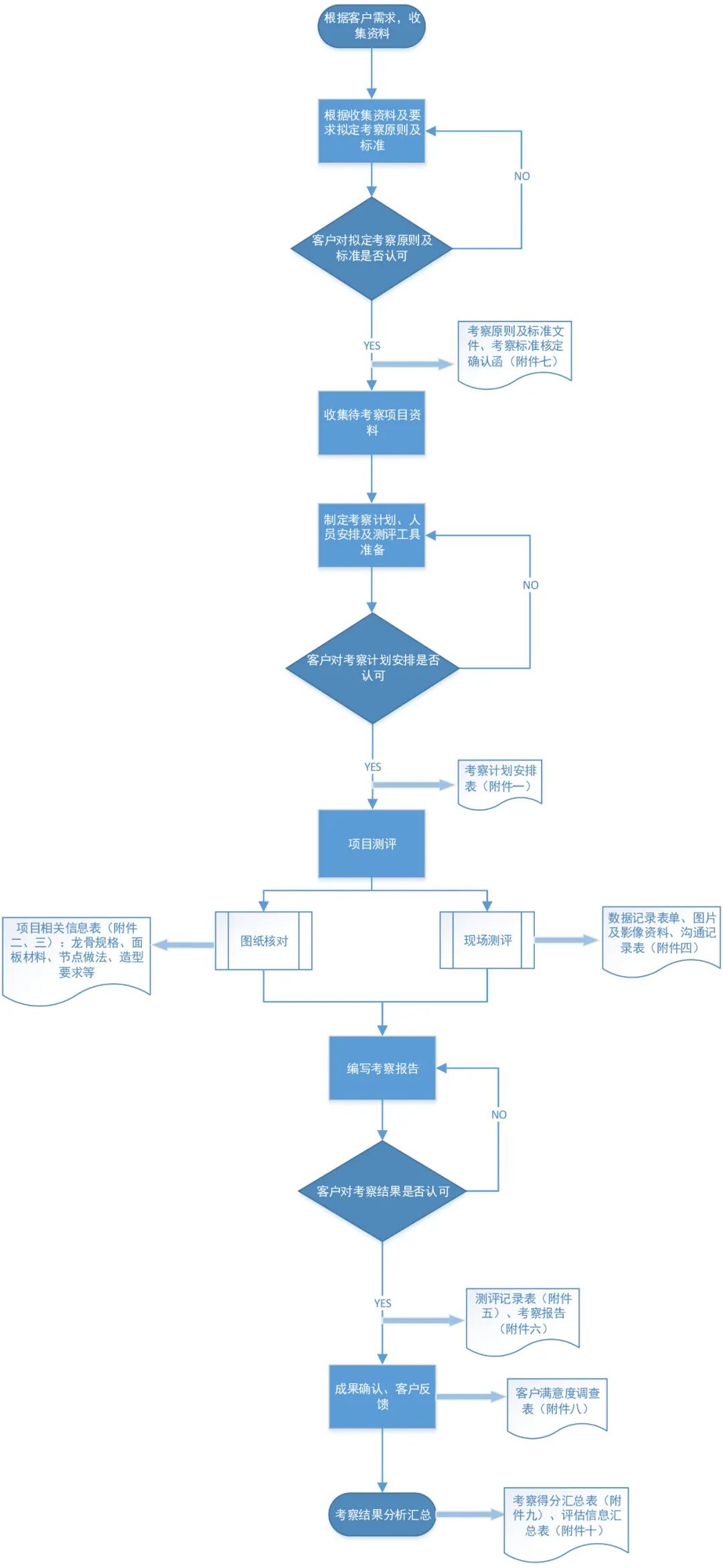

Help build a refined management system

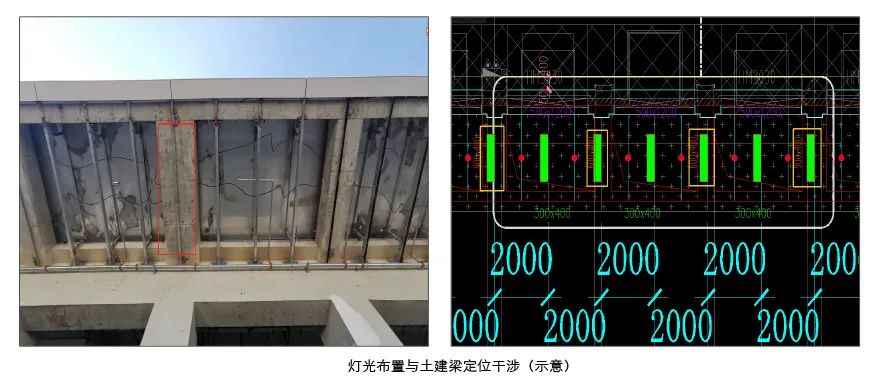

FORCITIS found in many project cases that excellent construction resources are an important step in the performance of project quality control, thus FORCITIS suggested that Party A should increase the investigation of construction resources.

△Operation flow of investigation on construction resource project

Building quality is the cornerstone of a city, and quality control is related to the life of the whole building. Our job is to improve the quality of buildings and make the city where we live better and safer.

△Work photos of engineering management engineers

△Project site