Xi 'an International Football Center

-

Location

xi'an

-

Client

Xi 'an International Football Center Operation Management Co., Ltd.

-

Design

Zaha Hadid Architecture + Hong Kong iDEA Design

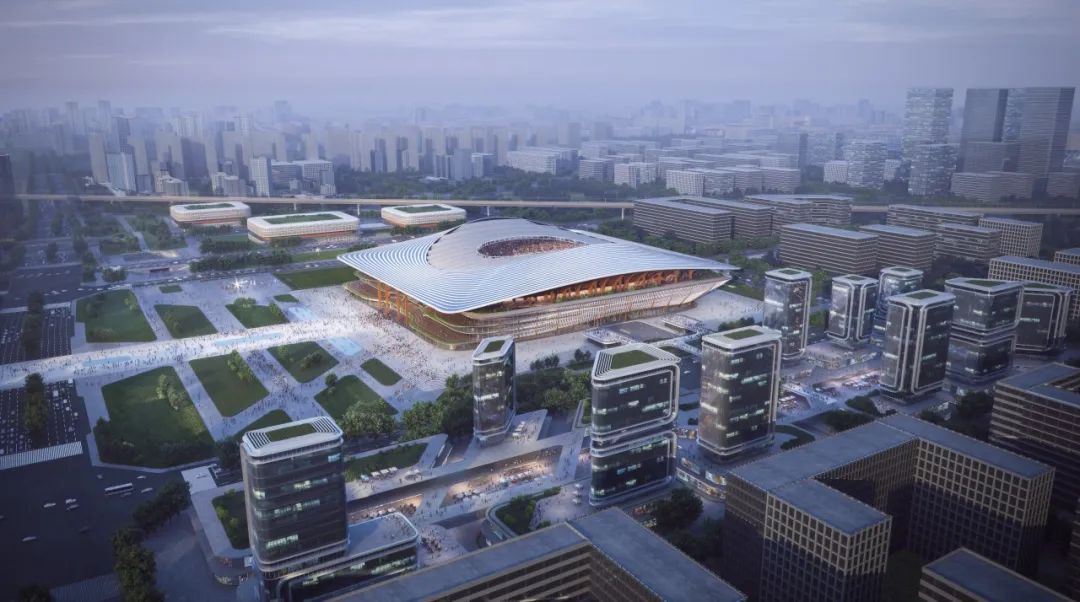

Xi'an International Football Center

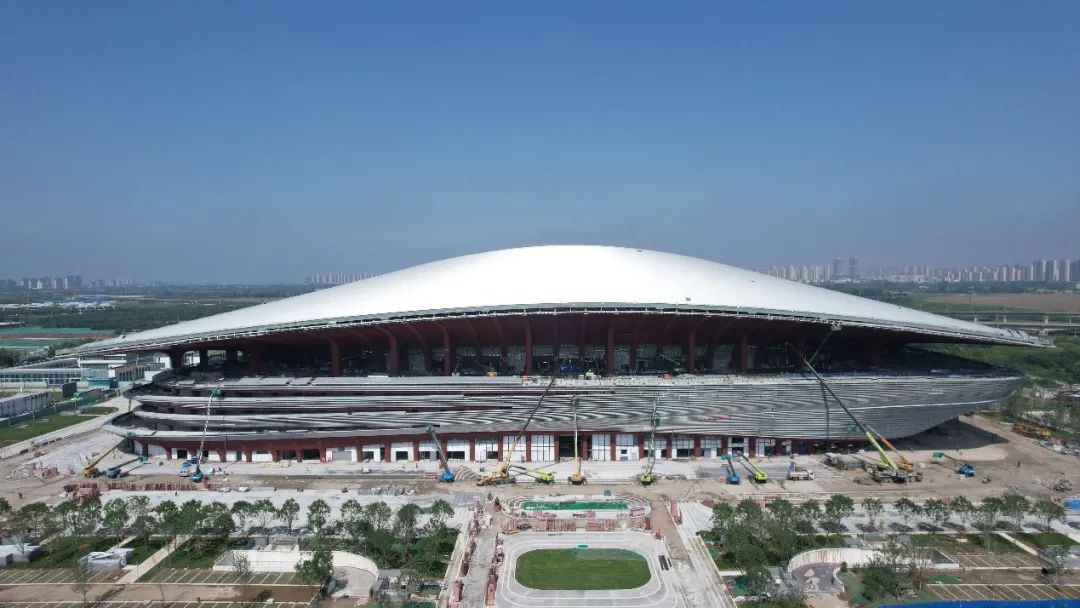

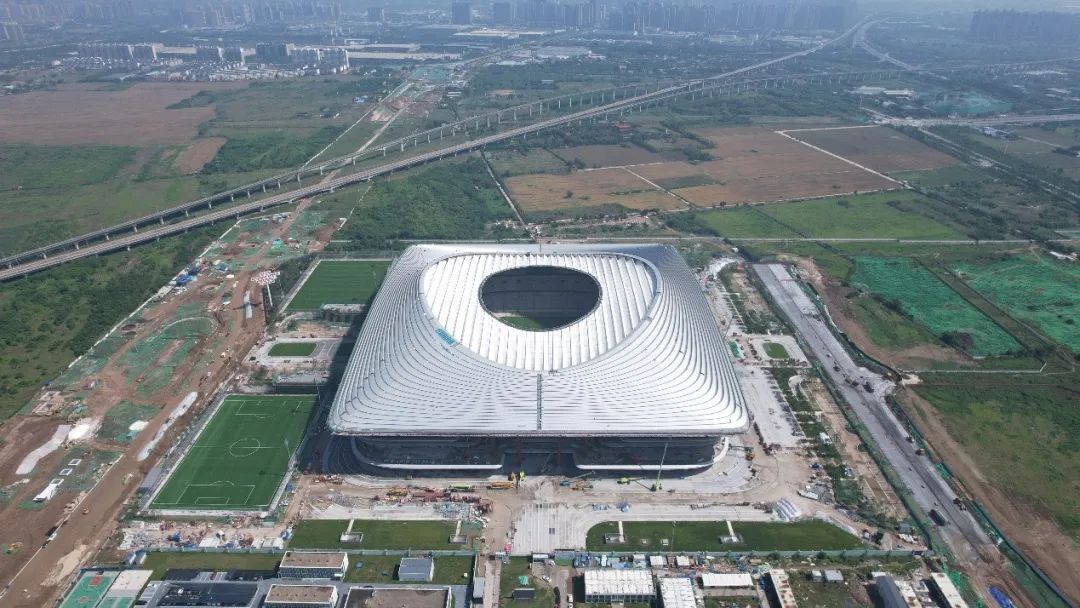

Xi'an International Football Center is about to be completed, which is the first international professional football field in Northwest China. This first-class stadium is designed and built according to the latest standards of FIFA and AFC, which can meet the needs of the world 's top football matches.

The project is designed by the Hong Kong iDEA design consortium led by Patrik 's British Zaha Hadid Architects and Gao Yan 's Hong Kong iDEA design consortium. The design integrates the characteristics of Xi 'an 's local ' Zhou Qin Han ' high-rise buildings. Through the large-span eaves and high columns, the content of Xi 'an 's historical and cultural heritage is skillfully integrated into the design to create a cultural landmark with strong locality and profound heritage.

FORCITIS has the honor to act as a curtain wall consultant for the whole process of the project. It was commissioned by Party A of Xi 'an International Football Center. From the construction scheme to the curtain wall construction landing process, it comprehensively understood the key and difficult points of the project, analyzed the possible problems in the design, production and construction of the project, and made suggestions on the project 's processing implementation plan and on-site construction plan from the perspective of standardization, convenience and construction period. Finally, it witnessed the smooth completion of the project.

The total land area of the project is 280 mu, the construction area is 250,000 square meters, the fixed seats are 60,000, the total height of the venue is 63.9 meters, the length is 299.6 meters, and the width is 254.5 meters.

The green building grade of Xi 'an International Football Center is two stars. The design concept adheres to sustainable development. In the whole life cycle, it saves resources, protects the environment, provides people with healthy, applicable and efficient use space, and maximizes the realization of high-quality buildings in harmony with nature.

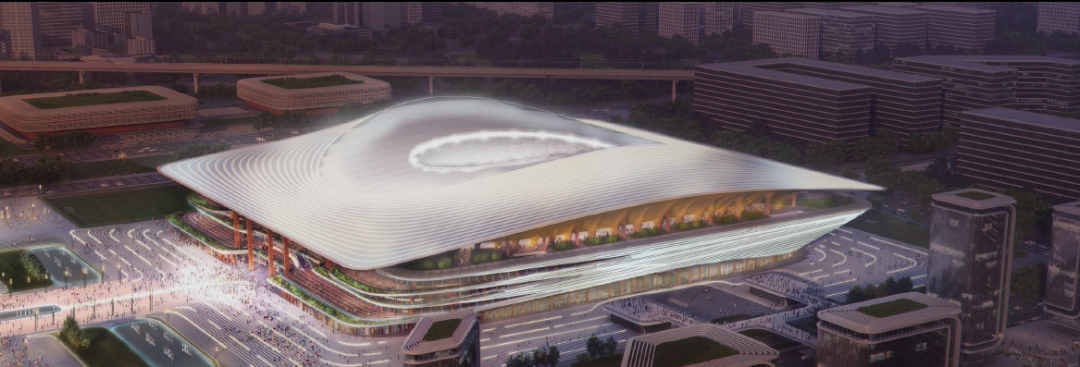

▲ The world 's first double-layer cable-net membrane structure large-span roof

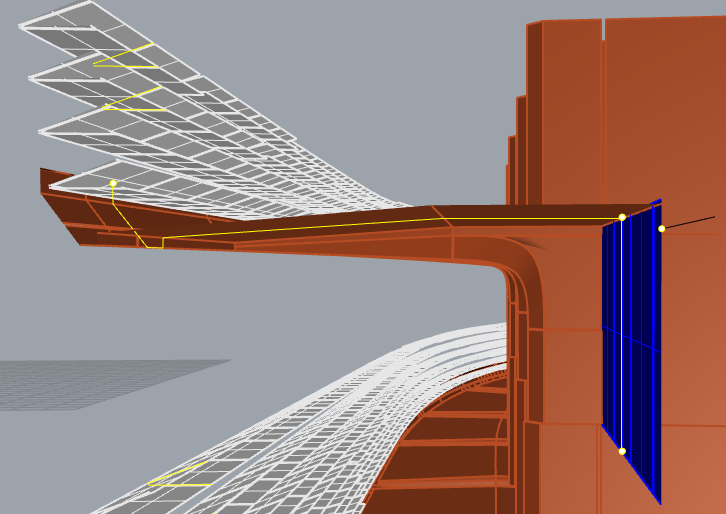

The design innovatively adopts the internationally first double-layer orthogonal large-span cable net system with internal openings, and cooperates with the cable-membrane truss unit design to form the world 's largest double-layer orthogonal internal opening cable net dome. The simple and light cable roof complements the elegant and dynamic facade lines, which not only fully demonstrates the cultural heritage of traditional Chinese architecture, but also subtly integrates the modern style of sports architecture.

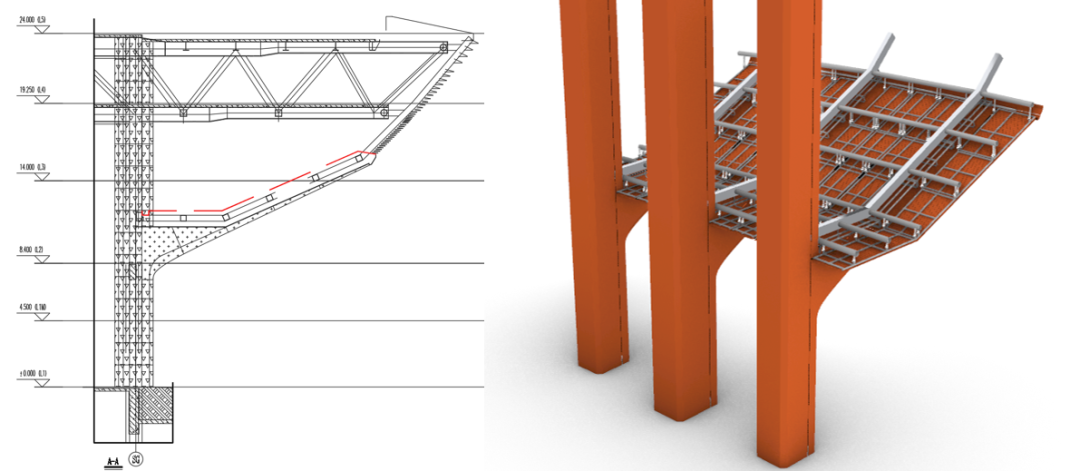

▲ Super large cantilever aerial greening platform

The roof gardens of the second, third, fourth and fifth floors of the building are both independent and coordinated. The peripheral landscape green belt weakens the curtain wall boundary of each platform and brings rich landscape experience to each platform.

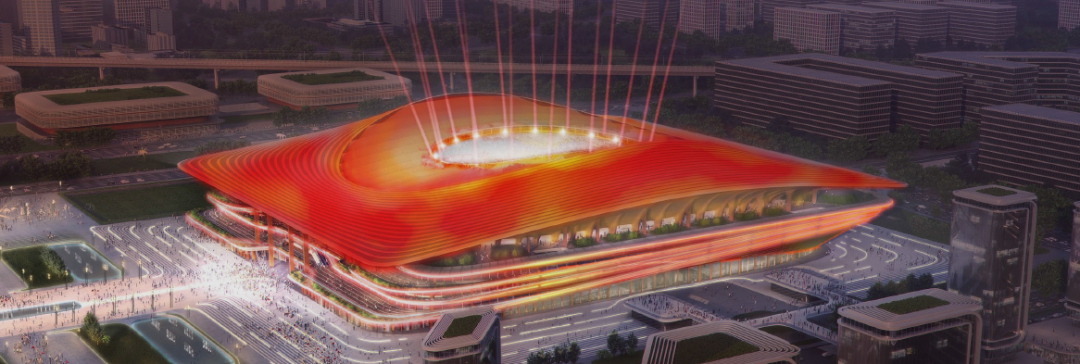

▲White light scene lighting on weekdays

▲ Competition scene lighting

The overall lighting effect of the outer facade simulates the dynamic changes of the sky and clouds in nature, and forms a hierarchical lighting effect at night. The competition shows wonderful activity color,. Usually realize the wonderful changes in the sky and clouds, guide the development of various activities, and fully demonstrate the popularity and public welfare. The venue lighting fixtures can effectively control various adverse conditions while meeting the lighting requirements of professional football matches, so as to meet the lighting requirements of high-definition TV transmission.

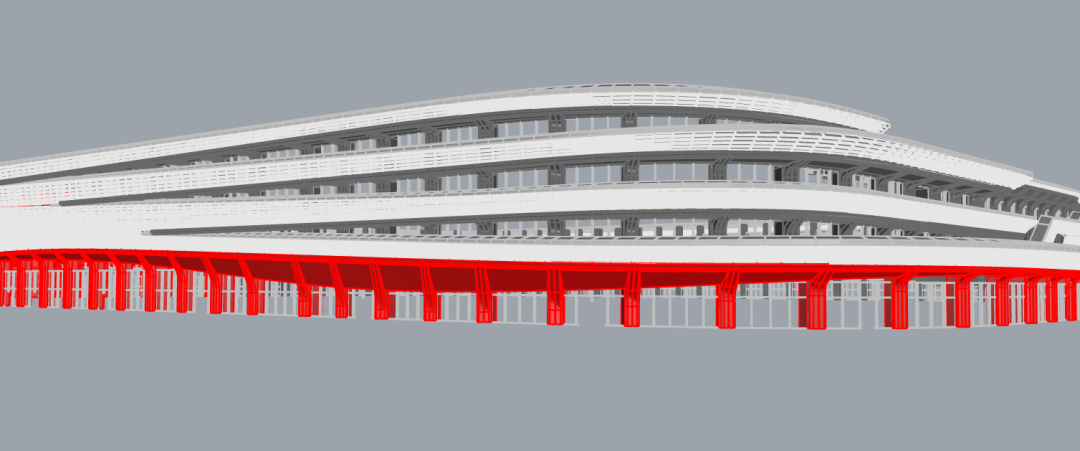

The progressive curve extension of the stadium outlines the beautiful geometric shape of the building. The material selection draws on the long tradition of Xi 'an. The traditional terracotta warriors and bricks inspired the choice of red pottery board as the main facade material. However, the panel of the facade space poses a challenge to the facade ceramic plate material. The ceramic plate is processed by vacuum extrusion, and the complex modeling ability is weak. The special-shaped plate needs to be spliced. Moreover, the clay plate is a brittle material, and the size of the ceiling material in the area with a large flow of people should not be too large, and safety measures should be added. After comparison, it is recommended to adjust the 1 ~ 4F column body and the 1 ~ 4F outdoor ceiling to the anti-ceramic UHPC board.

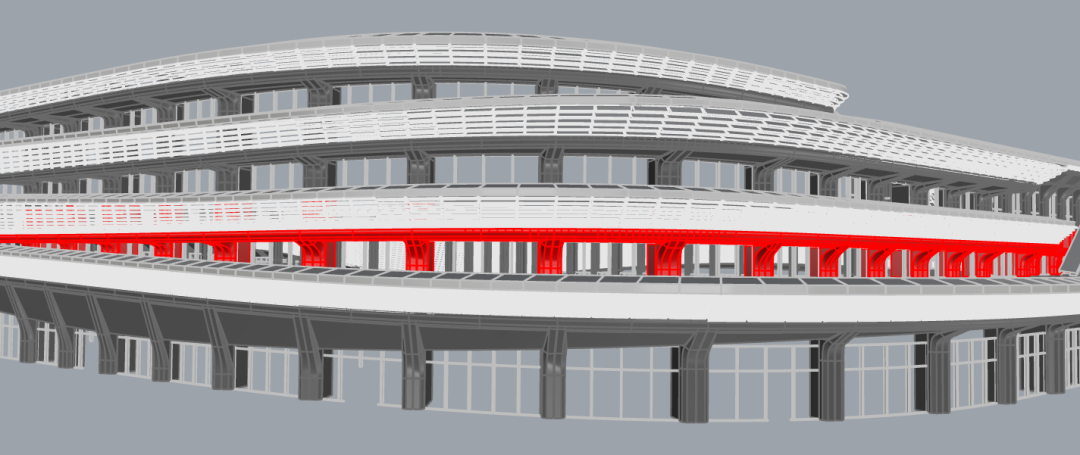

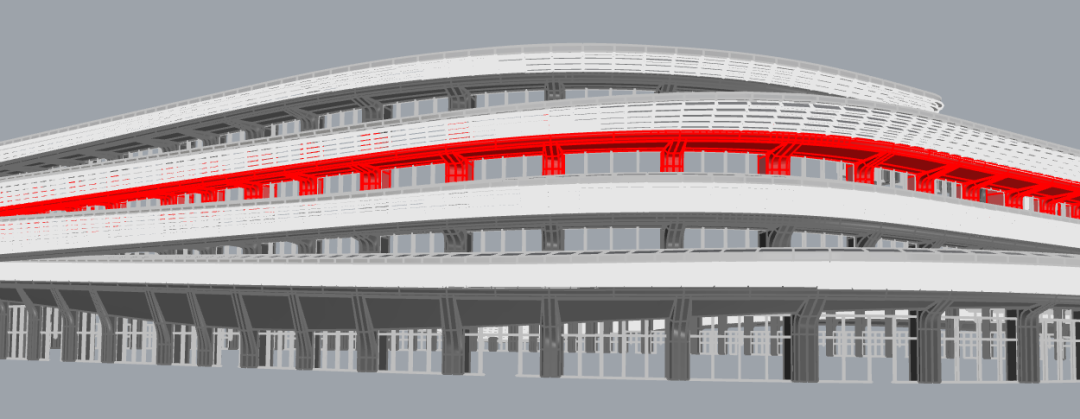

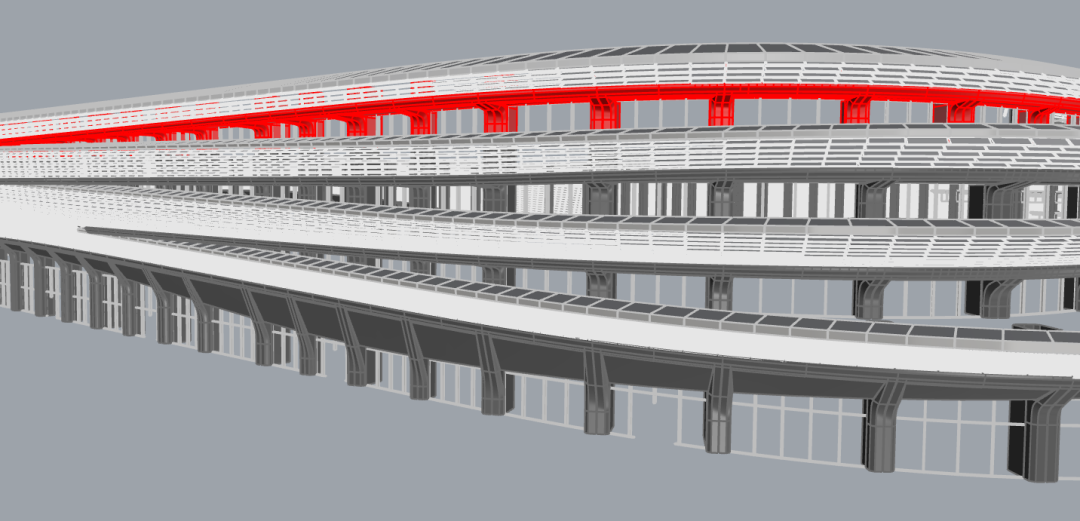

▲ 1F imitation ceramic UHPC curtain wall range

▲ 2F imitation ceramic UHPC curtain wall range

▲ 3F imitation ceramic UHPC curtain wall range

▲ 4F imitation ceramic UHPC curtain wall range

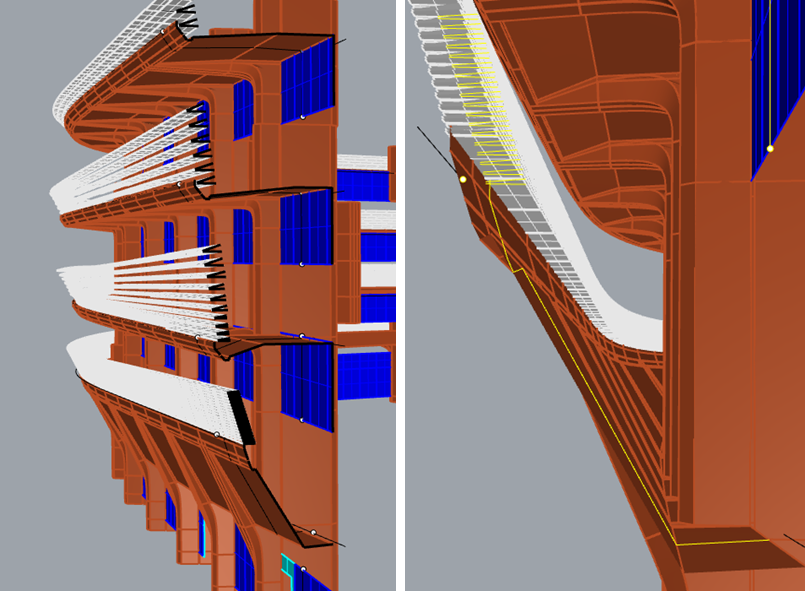

The toughness, deformation performance and impact resistance of UHPC ( ultra-high performance concrete ) assist the project to have higher modeling realization ability, which can realize single and double curvature, and can process large-size plates without affecting transportation and hoisting. On the plate division of UHPC, the ceiling and end line modeling are based on the original division, and the partial division is appropriately merged. In the direction of the ceiling section, the end line modeling is one piece, the rear is one piece, and the local large area is divided into two pieces at the fold line position. The position of more than 5m can increase the seam, but it cannot be centered to ensure the continuity of the seam.

The back plate is set behind the UHPC ceiling on the north side, and the back plate is not set in the position that cannot be seen indoors.

The safety of large-area UHPC ceiling panel was tested and studied, and the quality control of the factory was carried out during the construction process to ensure the quality of the upper wall panel.

▲ Slide left and right to view the scene diagram

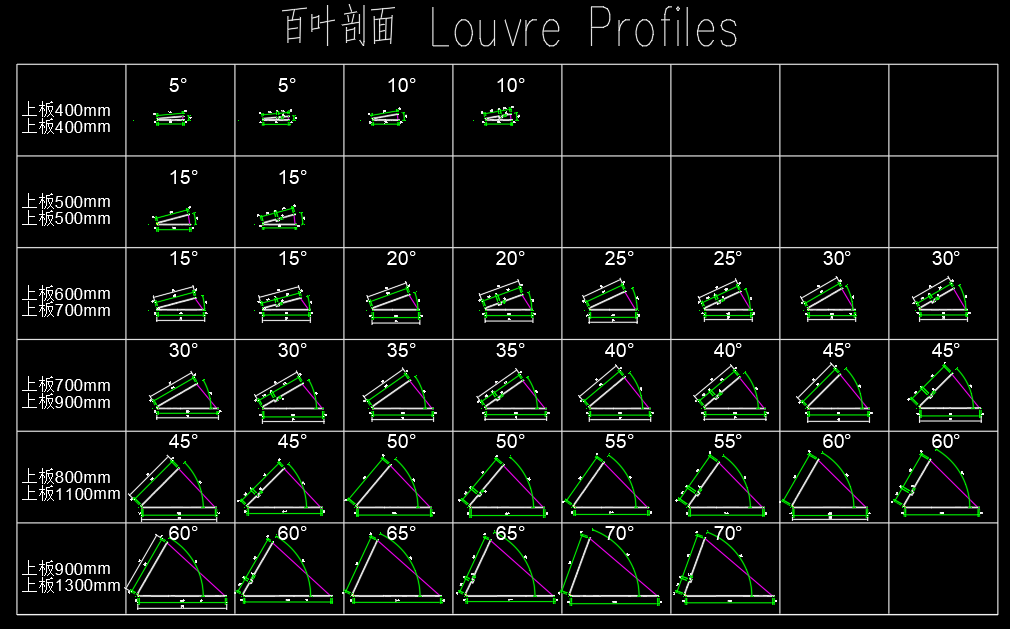

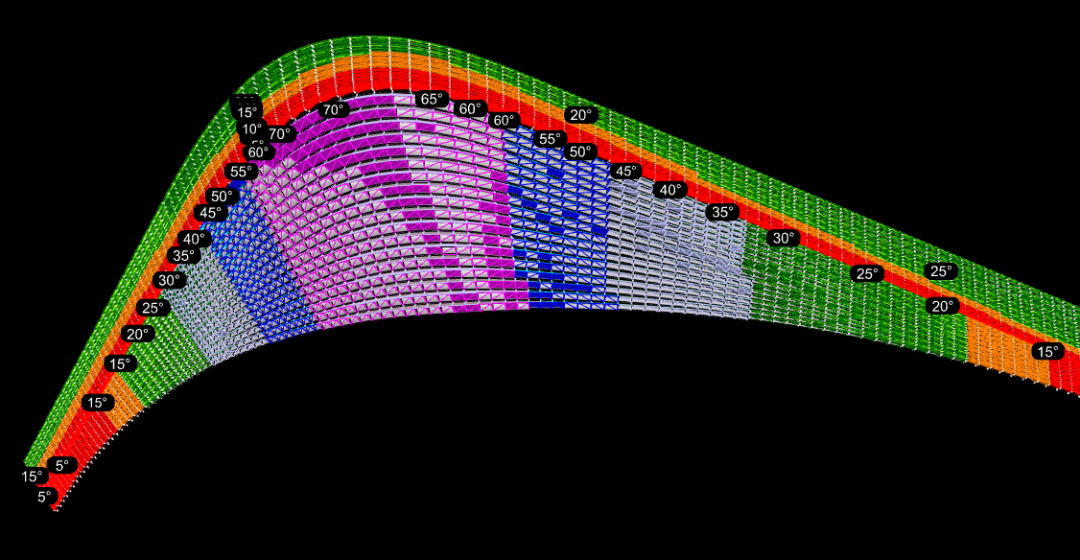

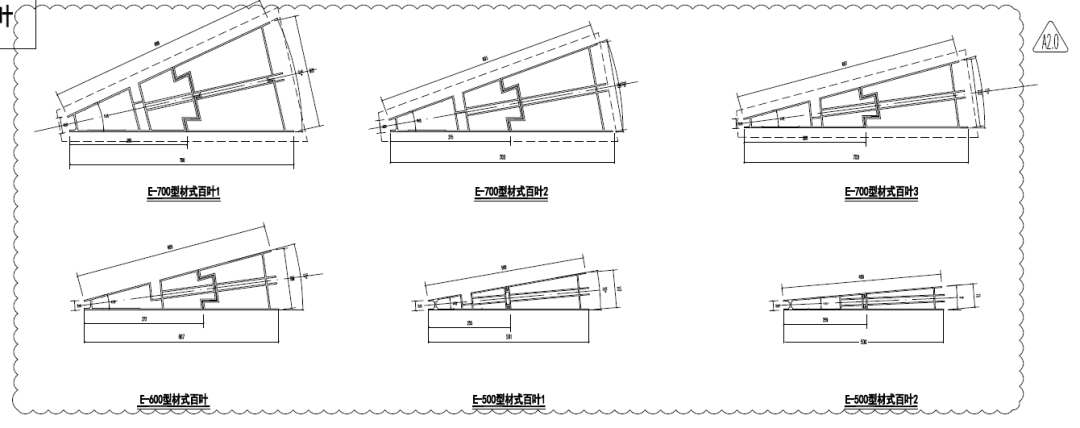

According to the opening angle and the length of the board, there are 36 kinds of louver ribbons.

The overall trend of the louver angle is gradual change in the direction of extension. However, the change of the two adjacent angles is a sudden change, and there is a height difference ; according to the communication results, the angle of smooth transition can be adjusted without affecting the cost and convenient construction.

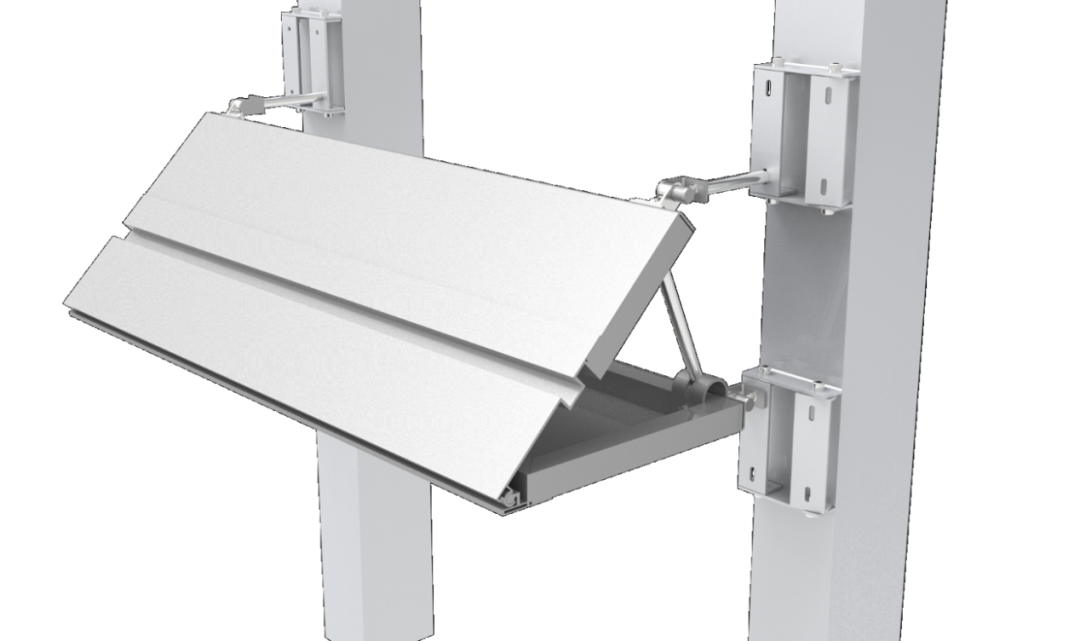

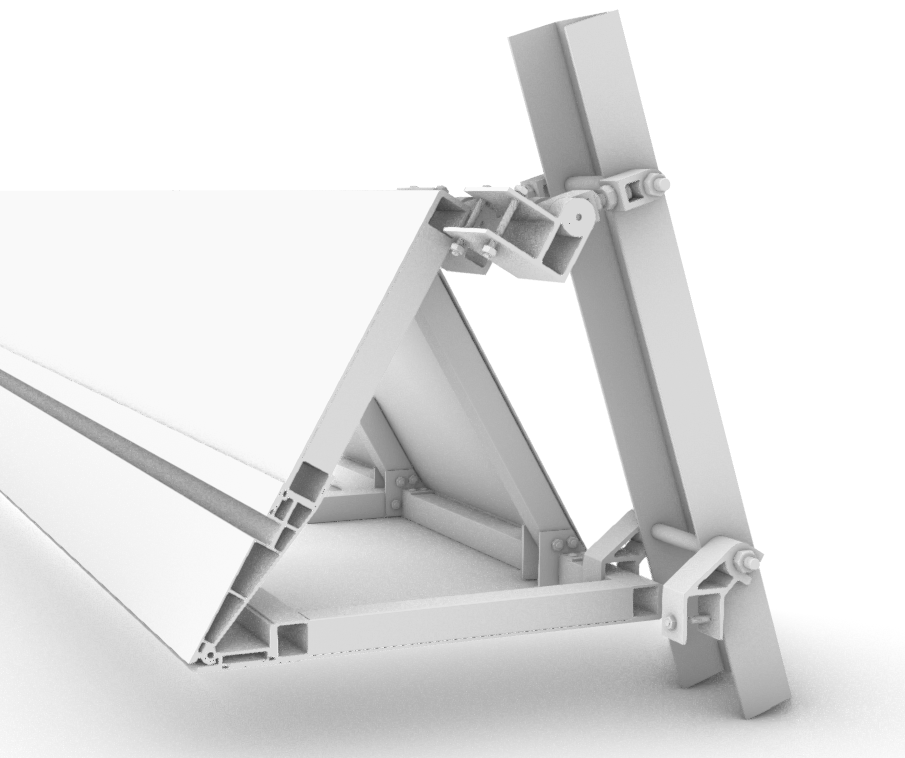

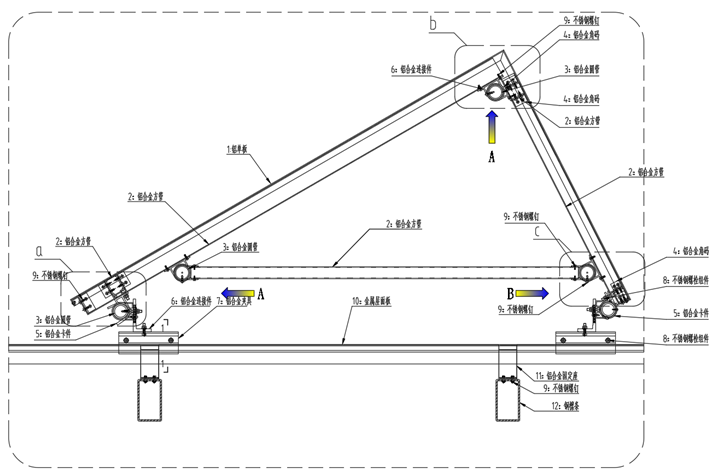

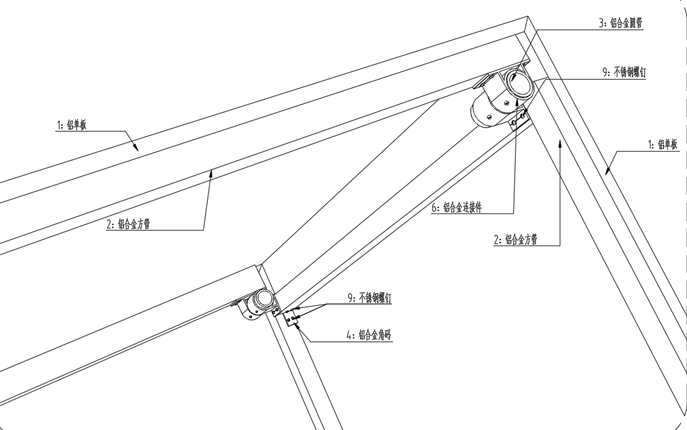

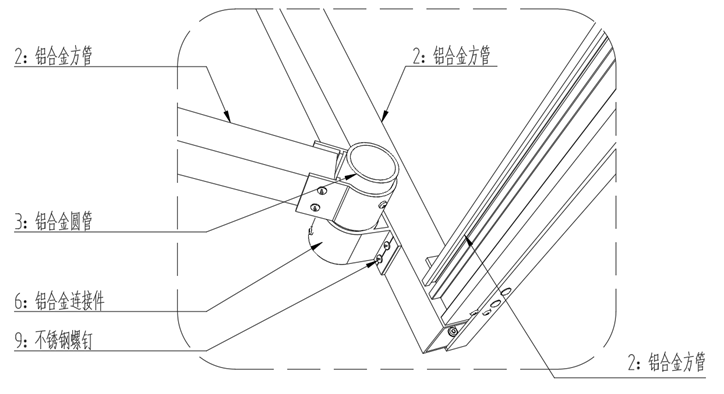

In terms of modeling realization, the opening and closing angle of the louvered ribbon of the facade aluminum plate is ≥ 25 °, and the front end of the louver is the profile, and the angle rotation is realized by the ball hinge. The back end is an aluminum veneer frame, which satisfies the adjustment of the louver depth change. After the angle is adjusted in place, it is fixed by the aluminum alloy square tube support rod to form a unit. The integral louver unit is connected with the main structure by aluminum alloy pendant.

The inside ribbon with a small angle is used, and the outer facade aluminum profile louvers ( opening and closing angle < 25 ° ) are used in the modeling realization. The panel adopts the open-die aluminum profile, and the front end is rotated by the ball hinge connection. The opening position adopts the screw to adjust the angle change, which can realize the smooth connection of the angle and restore the design concept.

▲ Small angle louver ribbon

▲ Slide left and right to view the on-site installation progress of the louver

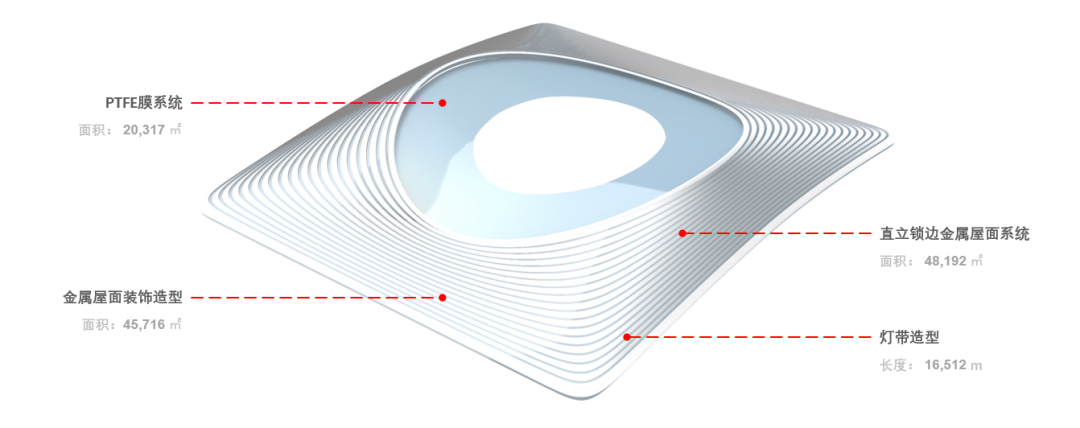

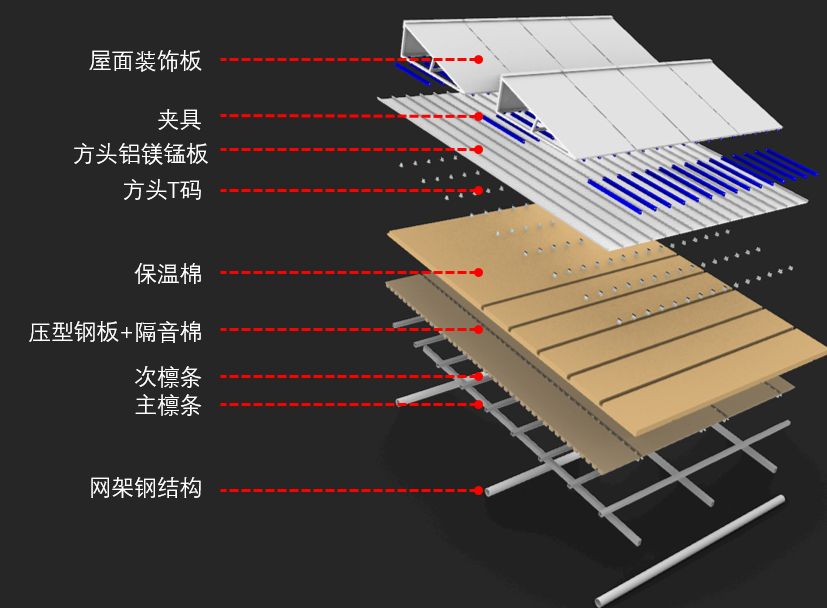

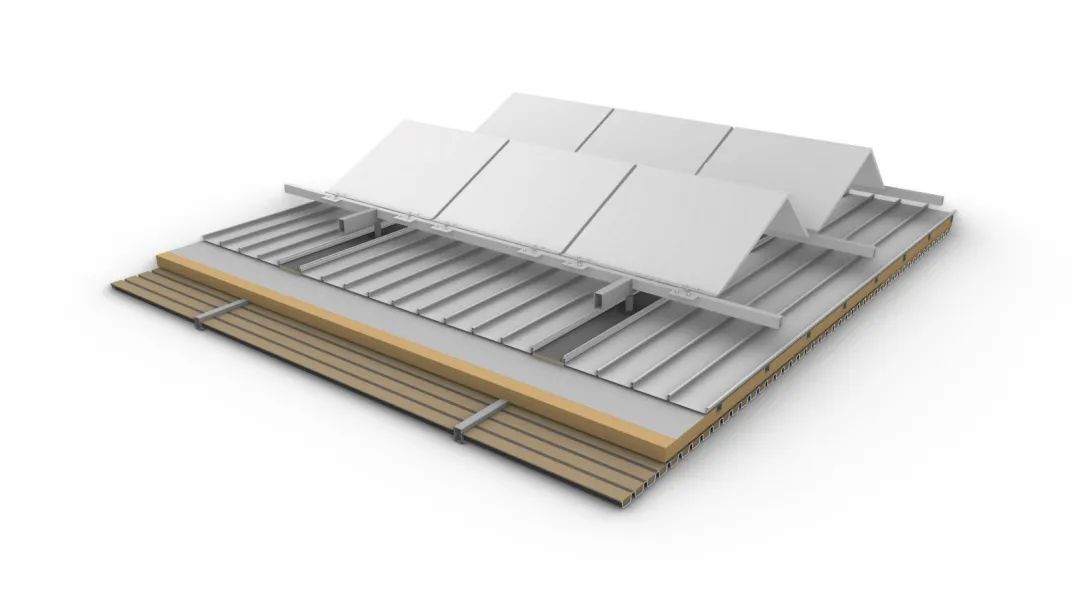

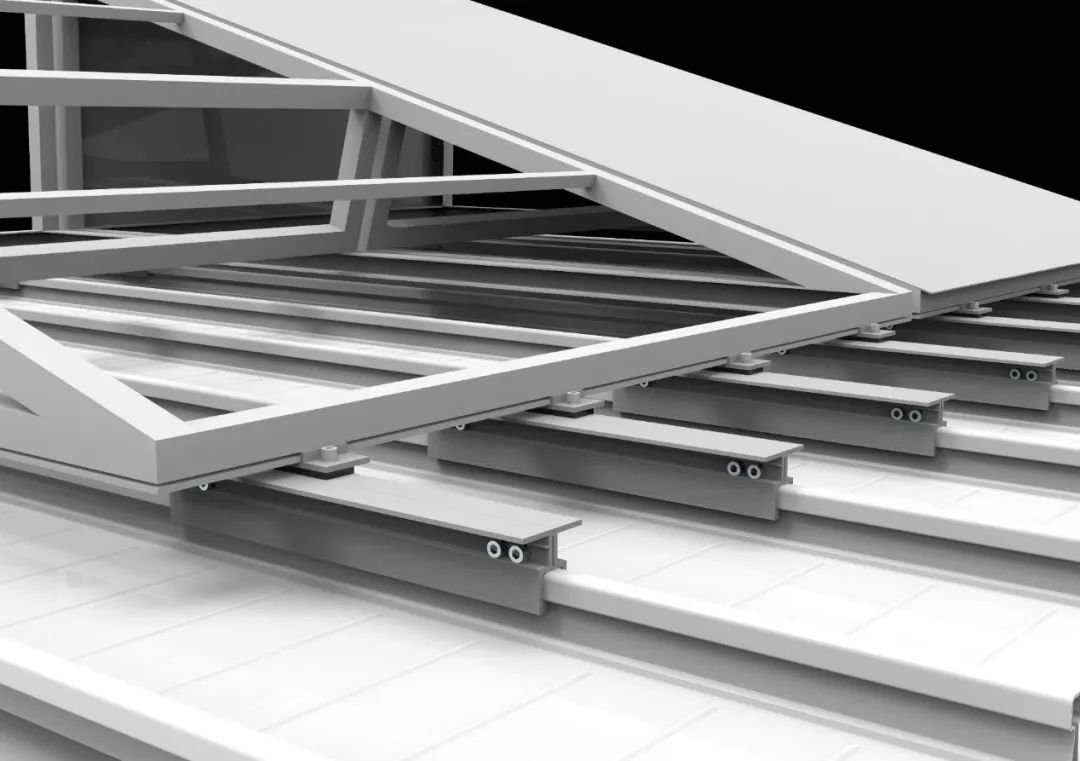

▲ Metal roof modeling

▲ Metal roof structure split

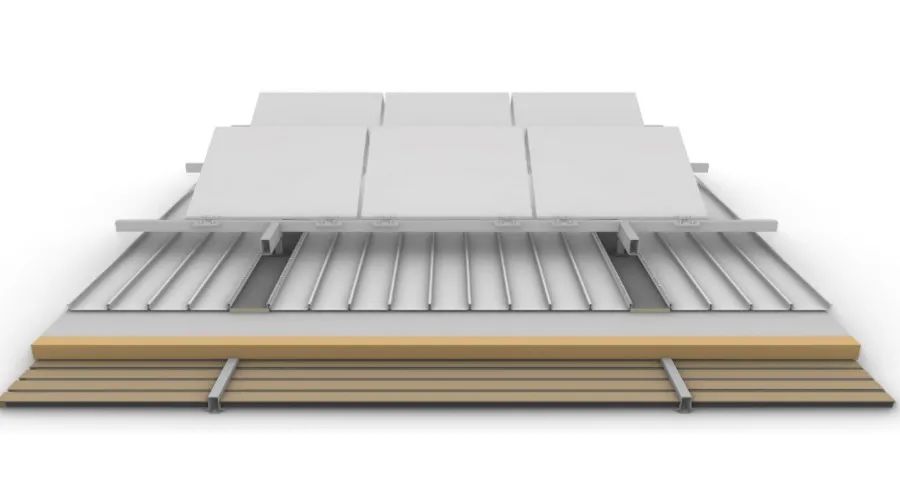

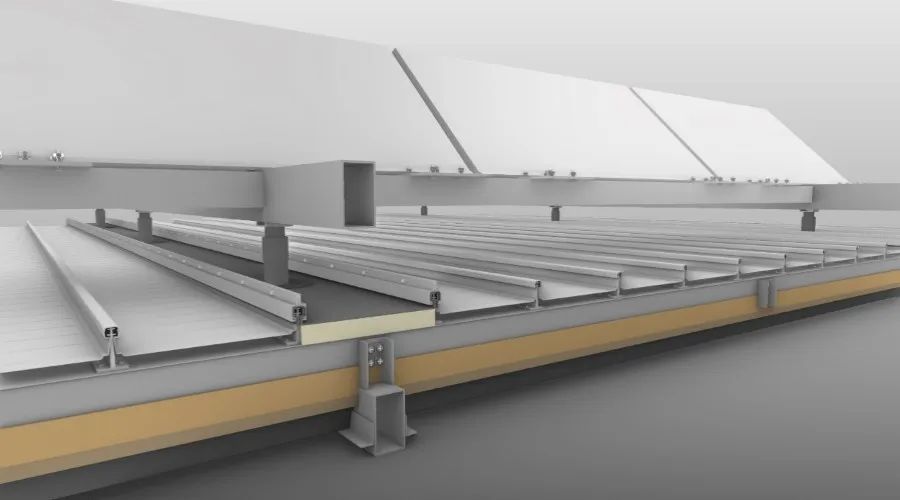

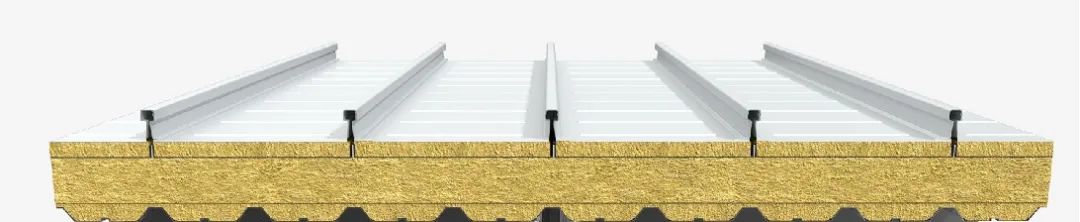

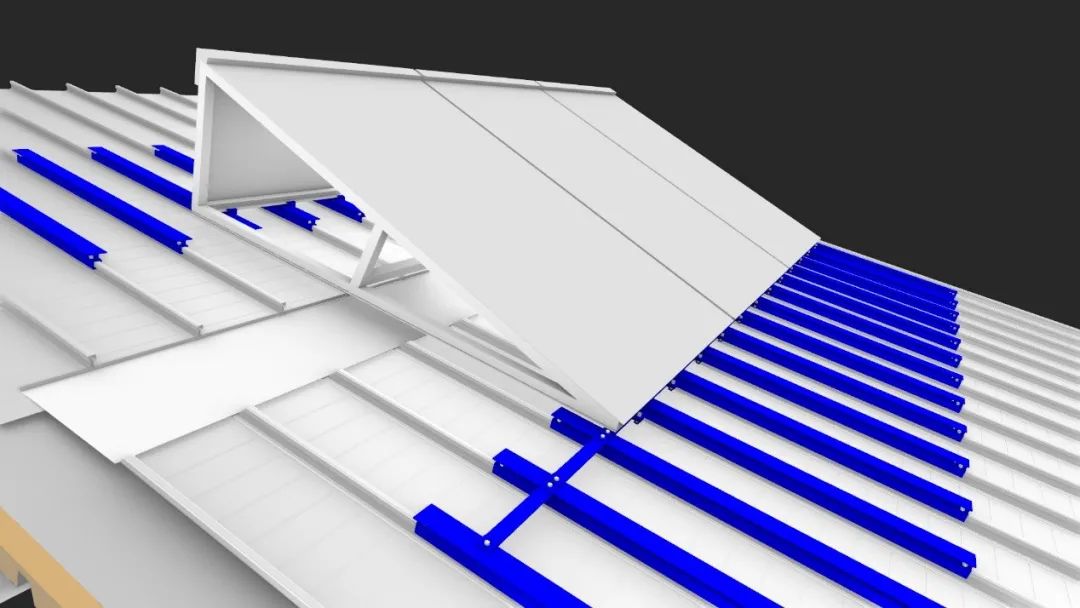

Waterproof measures : in order to solve the problem of heat insulation and steam insulation of the roof, tpo waterproofing membrane is placed on the roof. The frame is made of purlins and steel plates, and a special insulated T-type bracket is set on the steel plate ( to prevent ' thermal bridge ' ). The top of the bracket is extended into the cavity where the two side ribs of the two plates bite each other, and then the square head upright locking system roof is installed.

The process flow of the roof system is as follows : construction setting out → purlin support and purlin installation → 0.6mm thick YX35-125-750 perforated molded bottom plate installation → non-woven fabric and sound-absorbing cotton installation → 1.5mm galvanized steel plate installation → TPO waterproofing membrane installation → ' T ' code bracket installation → noise reduction cotton installation → square aluminum magnesium manganese panel production and installation → flooding board production and installation.

▲ Metal roofing system process diagram

The drainage plate is lapped in sections to ensure safety and reliability, and no water leakage.

▲ Drainage plate segment lap schematic

Water avoidance test : After the installation of the flame retardant waterproofing membrane and the fixed seat is completed, in order to detect whether the flame retardant waterproofing membrane layer is destroyed when the fixed seat is installed. We usually use water on the surface of the waterproofing membrane, mainly testing two places : one is whether the flame retardant waterproofing membrane is destroyed during the installation work, and the other is that the fixing seat installation screw penetrates the flame retardant waterproofing membrane and the floor structure layer, and there is no water seepage phenomenon.

▲ Water avoidance test

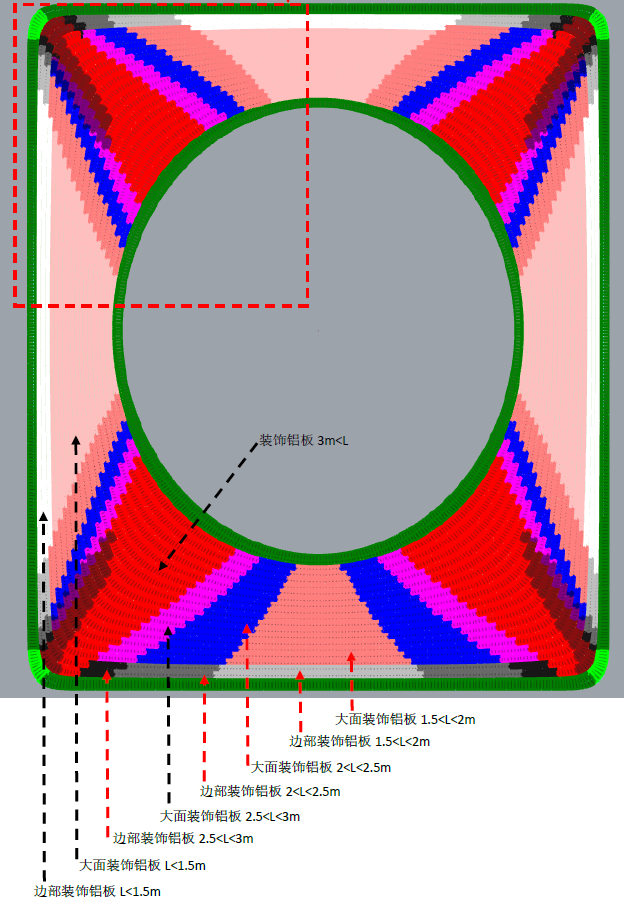

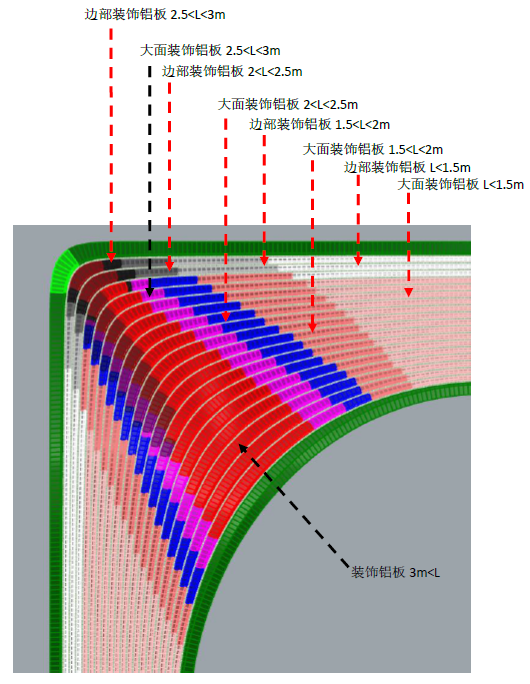

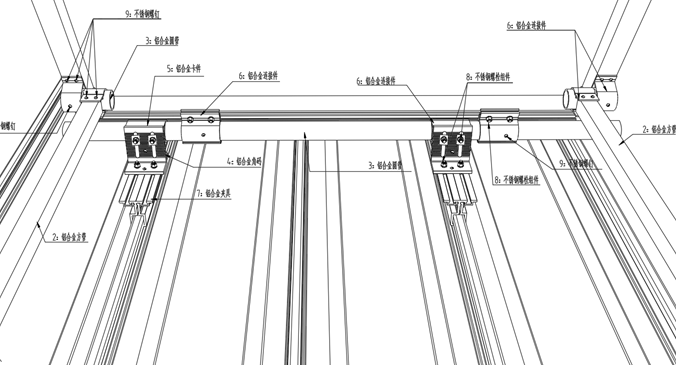

The decorative surface layer adopts the block sub-frame aluminum plate curtain wall. The outer decorative panel is a module unit, and the angle is a variable value. The pressure block is set at the intersection of the decorative panel and the roof panel rib. The pressure block is unequally arranged, the flatness is good, the floating connection is good, and the temperature influence is small.

The roof decoration board is made up of one module unit in the factory, which is transported to the site for direct assembly, so as to ensure the construction progress and quality.

▲ Decorative board module unit

The decorative plate unit is composed of profiles to ensure that the module has sufficient strength.

▲ Decorative board unit frame schematic

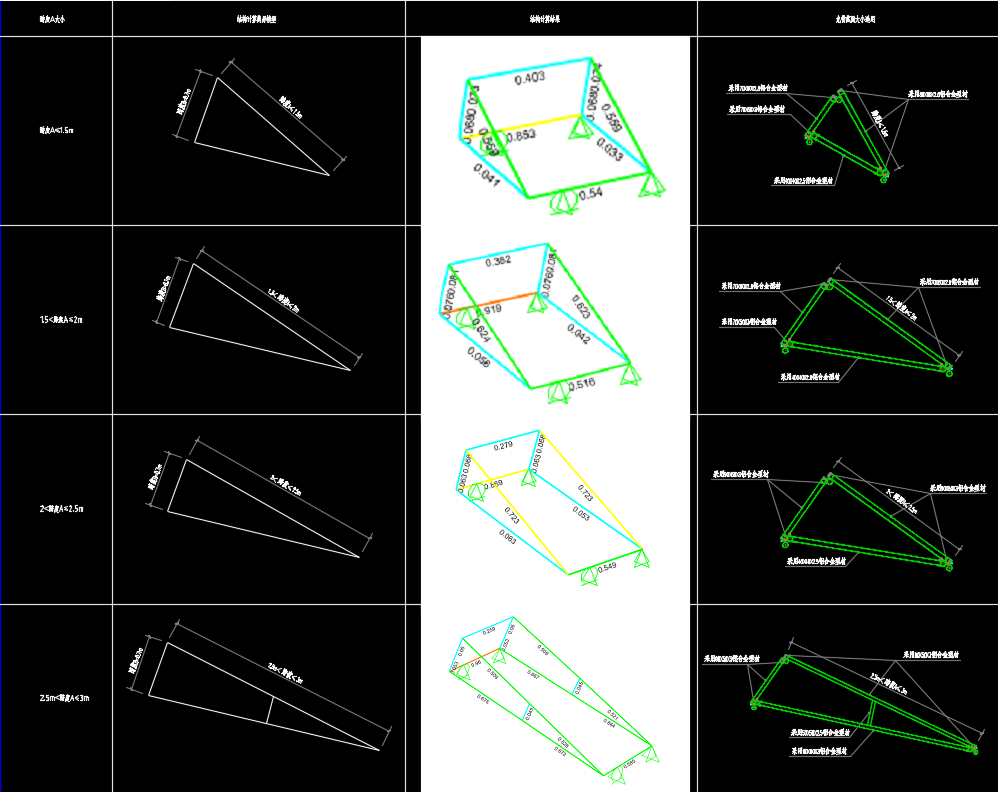

The keel structure is calculated and optimized for decorative panels with different span sizes.

▲ Different spans of keel

Roof decoration plate plate division

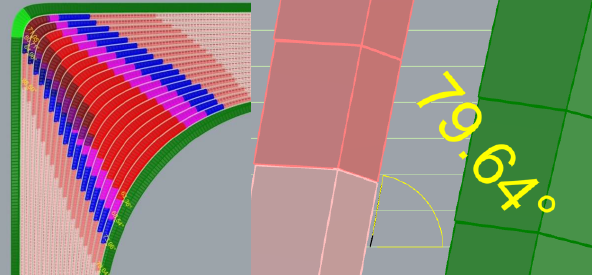

Angle between decorative panel and roof panel

The maximum angle of the L < 1.5m plate is 90-79 = 11 degrees, 1.5 < l < 2m < span = ', ' > the maximum angle is 90-74 = 16 degrees, 2 < l < 2.5m < span = ', ' > the maximum angle is 90-68.5 = 21.5 degrees, 2.5 < l < 3m < span = ', ' > the maximum angle is 90-63 = 27 degrees.

Through the variable angle roof decorative aluminum curtain wall system to adapt to different angles.

▲ Decorative aluminum plate element node section

▲ Short side direction hinge joint of decorative aluminum plate

▲ Short side direction hinge joint of decorative aluminum plate

▲ axonometric drawing

▲ Slide left and right to view the three-dimensional sketch of the roof structure

▲ Slide left and right to view the current installation of the roof

▲ The overall picture of the project

▲ Slide left and right to see more project reality maps

The current project progress video :

▲ The latest progress of Xizu site

In the future, Xi 'an International Football Center will focus on the green space environment, realize the scenery of the four seasons, and build a green venue that integrates sports supporting functions and ecological functions to meet the needs of major sports events. Also during the non-competition period, to meet the needs of citizens ' cultural performing arts activities, national fitness and fitness.

-

Zhengzhou International Cultural Exchange CenterNew architectural vocabularies are used in the design to project the spirit of jade into the national venue space and urban environment.

Zhengzhou International Cultural Exchange CenterNew architectural vocabularies are used in the design to project the spirit of jade into the national venue space and urban environment. -

Suzhou Orchestral Concert HallA folk music hall carrying classical and modern, strings and culture breaks ground, bringing a strong visual and aural impact to the world!

Suzhou Orchestral Concert HallA folk music hall carrying classical and modern, strings and culture breaks ground, bringing a strong visual and aural impact to the world! -

Dehong International Middle School in Qujiang, Xi'anThe building focuses on creating a simple, warm and vibrant campus environment.

Dehong International Middle School in Qujiang, Xi'anThe building focuses on creating a simple, warm and vibrant campus environment.